What is ABC Analysis For Inventory Management? Benefits, Limitations and Best Practices to Effectively Carry Out ABC Analysis in 2022

Recent studies show that inventories hold over $1.1 trillion in cash or 7% of the U.S. GDP. This indicates that more money than you could make from sales is sitting in your warehouse.

The majority of businesses today struggle with adequately managing their inventory. After all, when juggling a variety of consumer requests, keeping the ideal inventory quantity can be challenging. However, you can manage your goods effectively with a robust inventory control system.

Inventory management helps companies have the right amount of merchandise on hand. As a result, many sectors, including eCommerce, manufacturing, logistics, retail, and other enterprises that deal with inventory, place it at the top of their priority lists. ABC analysis is one of those several inventory control strategies.

- What is ABC Analysis For Inventory Management?

- Why Utilize ABC Method of Inventory Control?

- Limitations of ABC Analysis For Inventory Management.

- How is the ABC Analysis For Inventory Management Carried Out?

- Best Practices and The Most Effective Approach For Applying ABC Inventory Analysis

- Conclusion

- ABC Analysis For Inventory Management FAQs (Frequently Asked Questions)

What is ABC Analysis For Inventory Management?

Inventory management teams utilise ABC inventory analysis to divide their stock into three groups, A, B, and C, according to the “value” or “importance” of each group to their particular organisation. Managers can direct their attention and resources toward controlling stock which is more important by using the very straightforward ABC analysis. To ensure they carry the ideal levels of the appropriate goods, they may also modify their inventory control procedures for each category.

A system for controlling inventory is utilised in the ABC method of inventory control; this system is used for materials and throughout the distribution management. It is often referred to as SIC or selective inventory control.

In the ABC analysis approach, inventory is split into three groups, A, B, and C, in order of decreasing value. The things in category A are the most valuable, followed by those in class B, which are less valuable than A, and those in category C, which are the least useful.

Management and control of the inventory are essential for a firm. They assist in keeping their expenses in check. The ABC analysis enables management to concentrate on the highest-value things (the A-items) rather than the numerous low-value products (the B-items), which helps the firm regulate inventory. Read our blog on inventory accuracy to understand how to achieve high inventory accuracy for operational efficiency in 2022.

How Does the Pareto Principle Relate to ABC Analysis?

According to the Pareto principle, commonly referred to as the 80/20 rule, 80% of results are brought about by 20% of the inputs.

Vilfredo Pareto, an economist from Italy, saw that just 20% of the pea pods he planted produced the majority of the peas in his garden, which led him to develop the concept that bears his name. More crucially, he discovered that 20% of the population in Italy held 80% of the country’s land, which led him to detect a similar ratio.

Since then, the Pareto principle has altered how economics is researched and how we comprehend how the world’s resources are distributed.

The Pareto Principle, which states that typically 20% of an organization’s inventory accounts for 80% of its value, is the basis of ABC inventory analysis. Using this knowledge, leaders can make well-informed decisions.

The application of Pareto’s Principle to rank and prioritise particular inventories over others is one way it contributes to ABC analysis. By organising your goods into three categories, ABC analysis simplifies inventory analysis and empowers you to make more strategic choices.

ABC Classification of Inventory

The ABC analysis is one of the most popular inventory management techniques. Based on the degree of value any item has within a firm, the ABC analysis divides it into three categories (A, B, and C).

Businesses may better prioritise their inventory, streamline processes, and make informed decisions by classifying their inventory using ABC analysis.

The ABC classification of inventory, as the name implies, divides inventory into three main categories:

- Segment A- Goods falling under category A are the most valuable and essential items. About 20% of all products comprise segment A products, which generate 80% of your company’s income. It is regarded as a niche market with few products but high sales.

- Segment B– Products in category B are somewhat more expensive than those in segment B. However, it controls 30% of the product market and generates 15% of the income. In addition, although more items are in this category, they are less valuable.

- Segment C– Products falling under category C are numerous but less effective at bringing in money. Comparatively to categories A and B, sector C has the highest stock ownership at 50% but only produces 5% of the revenue.

Why Utilize ABC Method of Inventory Control?

Despite having many stock-keeping units (SKUs), most enterprises have not been able to grow or expand their businesses considerably. Businesses must deal with a wide range of additional inventory management difficulties. Lack of stock information, a poor management system, trouble managing personnel, a lack of space, and other issues might be problems.

This issue is resolved through ABC analysis. It can help businesses in inventory optimisation and streamline their inventory management. Let’s examine the 5 benefits of ABC analysis in inventory management.

Analyze Industry’s Demand for a Product

After manufacture, each product passes through four stages: dispatch, growth, development, and decline. After a certain point, the product’s demand in the market starts to decline as it reaches its actual value. You might refer to it as a product’s life expectancy rate. Additionally, a product’s lifespan is determined by the customer’s demands.

ABC analysis aids businesses in determining client wants. Businesses often overestimate the product demand and end up stocking up on excess. ABC analysis ensures that you know what your customers desire so you can ban that dark room from your firm.

Due to this, you will be able to efficiently and successfully manage your inventory. You will only place orders for what your consumers desire, neither more nor fewer than is necessary.

It’s essential to remember that if a product’s demand suddenly increases on the market, the product’s decline will be further postponed.

Enables Supplier Negotiations

Using ABC analysis helps negotiate a reasonable price for a product with a supplier. Watch to discover how.

For instance, if you are negotiating with a supplier for a product in the A category, you are aware that you must make the most significant investment possible since it brings in the most money for your business. You can entice the provider with any additional benefits from your end if they are reluctant to make you a reasonable offer or accept your offer. Perhaps a form of agreement that you will purchase the following shipment of items from the same vendor.

Consequently, you’ll get a reasonable price that suits your needs and save more money on items in the A category, resulting in more advantages.

Enhanced Customer Service

When you don’t know the precise amount of inventory you need, you may overstock on items that won’t even be useful to you. Then, instead of stocking up on things your clients might want, you fill up on useless items.

You may utilise ABC analysis to determine precisely what your consumers desire or are seeking. Consequently, you will be able to meet client needs and grow your business. As a result, you’ll spend less on things you don’t need and concentrate on buying something that will make you money.

Additionally, you will cut down on inventory expenditures that you could be squandering on products that don’t appeal to your target market.

Goods Manufacturing

Manufacturers may enhance their cycle of stock renewal by using ABC analysis. It enables them to make things based on their yearly cost rather than randomly. As we have already explained, what frequently occurs is that we often anticipate demand.

This presumption causes the manufacture of unnecessary commodities stocked in the warehouse where they will sit for the longest. Consequently, your items are ruined while in the warehouse, which is the greatest nightmare any business owner can have.

Manufacturers may use ABC analysis to determine the value of their items so they can produce just those in high demand and less those in low demand.

Warehouse and Supply Chain Management

The ABC analysis inventory control method is used to enhance a company’s stock count cycle. For instance, commodities in Category A of the ABC analysis are tallied every three months, those in Category B are counted every two years, and category C products are only computed once a year. Doing this means you no longer entirely disregard your inventory status or waste too much time monitoring it.

When you have A category items that bring in excellent revenue, you want to regularly check to ensure they are always in stock, if not in plenty.

You frequently refuse to concentrate on the condition/status of your warehouse in terms of stocks when you don’t know what your items are worth or imagine they are worth. This might result in goods running out or stock waste.

These are some of the powerful advantages of ABC analysis that business owners shouldn’t give up.

Limitations of ABC Analysis For Inventory Management.

ABC analysis is not a one-size-fits-all inventory management solution despite its inventory management and maintenance advantages. The usage of an ABC analysis is impacted by the unique consumer demand patterns, classifications, systems, and difficulties each firm faces.

The focus on the financial worth of inventory and the sizeable amount of time and discipline required to use the approach are two drawbacks of ABC analysis. Here are some more difficulties:

Parameter Instability

According to ABC analysis, managers frequently allocate up to 50% of items to a new category every quarter or year. Since organisations sometimes don’t become aware of the changes until there is a demand issue, the necessity to reevaluate might waste time and harm customer happiness.

Limited Pattern Consideration

The traditional ABC approach will not consider elements like new product launches or seasonality. For instance, the lack of a prior customer base may explain a new product’s low sales volume. When demand is changing or unclear, ABC analysis will produce inventory inefficiencies since it provides a relatively static view of demand.

Low Information Extraction

Information from the ABC class might not have all the statistics or detail required to make educated decisions.

High Resource Consumption

An unpleasant outcome of ABC analysis is bikeshedding, which is the practice of giving excessive weight to unimportant matters. Staff members may add their ideas or seek variations since ABC analysis is simple to understand, turning it into a resource-intensive process rather than a time-saving instrument.

Value Blindness

ABC analysis bases a product’s essential judgement on its sales volume or usage frequency, yet some goods may defy this paradigm. A retail display item could, for instance, sell very little yet draw a lot of consumers (who will buy other things) because of its novelty. In the aerospace industry, a particular component for a plane could not be utilised frequently and have low market value, yet it might provide a crucial safety role.

System Incompatibility

ABC inventory analysis does not adhere to widely accepted accounting rules (GAAP) and contradicts conventional costing methods. Running numerous costing systems will increase labour expenses and inefficiencies.

Issues Of Under or Oversupply

There is a chance of running out of Class B or C products since the ABC analysis looks at dollar values rather than the volume that moves through inventories. However, the inverse can also take place. If you repeatedly order low-class things without reviewing them, you can end up with excesses that build up in your inventory.

Loss Risk

Just because B and C products aren’t as valuable as Class A ones don’t imply they are worthless. One of the ABC analysis’s shortcomings is that surplus stocks are constantly at risk of deterioration or damage. As a result, routinely uncounted or unmonitored merchandise might be stolen.

Mandatory Standardization

The ABC technique can only be effective if all components are subject to mandatory naming, storing, rating, and monitoring standards.

Arbitrary Categorization

Classifying items relies on the manager’s expert judgement without established parameters or consensus criteria for each group. As a result, this method may be entirely subjective.

Business Restrictions

ABC analysis is not helpful for businesses with an equal yearly consumption value of inventory items by type. For example, a firm that offers identical versions of goods like candies, nails, or socks might be unable to arrange stock according to the Pareto Principle.

High Resource Consumption

Employing more people or purchasing specialised equipment will be necessary for businesses with many inventory products to manage their inventory using ABC classification.

How is the ABC Analysis For Inventory Management Carried Out?

The most straightforward strategy to adopt ABC inventory management is determining if it will work for your company first. By addressing insightful queries, avoid making a lot of assumptions. Make all essential preparations for a smoother execution as soon as you decide to move forward.

5 steps to carry out ABC analysis for inventory management are as follows:

Examine Your Present Setup

To use ABC analysis, you must determine whether your present system can function well under the ABC methodology. For example, you may need to redesign your whole inventory management system if your existing setup does not enable you to give some things more priority than others. This may be costly, time-consuming, and generally annoying.

You must ensure that your inventory cost and consumer demand data are correct before you can begin employing the ABC method for inventory control. This is because cost and demand are crucial factors in defining each item’s utilisation value; without this information, you won’t be able to differentiate between which things to put in category A and which to put in category C.

Determine Values

It’s time to begin determining how each item benefits your company. This is how:

1. Select the time frame for your study. You can only look at sales for the most recent month or quarter. Still, many organisations choose to utilise annual consumption value, which examines the volume and cost of goods sold throughout the previous year.

2. To get the consumption value of each item, multiply the quantity sold by the cost per unit.

Units sold times price per item equals usage value.

3. Add up each product’s unique consumption numbers to get the worth of your overall inventory.

Product utilisation value from item 1 plus item 2 equals total inventory value.

4. Arrange the items (in your Excel spreadsheet or other application) according to the highest utilisation value to the lowest usage value.

5. Divide the product’s inventory value from the overall inventory value, then multiply the result by 100 to determine each item’s cumulative worth. You should now know what portion of the cost of your entire inventory may be allocated to each item.

(Product Inventory Value / Total Inventory Value) x 100 is the cumulative value.

Remember that while most inventory planning allows for manual calculation of these values, any inventory management software that supports ABC analysis ought to be able to calculate these values for you automatically.

Determine The Parameters

The Pareto principle, which essentially states that the bulk of any effect arises from a relatively small share of the causes, forms the foundation of ABC analysis. When applied to ABC analysis, this suggests that the majority of the overall consumption value of your inventory is assigned to A goods. At the same time, B and C items account for a smaller portion of that value.

The specific amount of inventory items and consumption value allotted to each category is up to you. Your values should, however, typically fall between the following ranges:

- Items A comprise 10%–20% of your inventory and represent 60%–80% of your yearly consumption value.

- B products, which makeup 20%–30% of your inventory and represent 20%–30% of your yearly consumption value

- C goods make up 50%–70% of your inventory and 5%–15% of your total sales.

Arrange Inventory Items

You may organise your stock goods into groups based on the criteria you predetermined in advance if you know how much each item in your catalogue contributes to the overall utilisation value of your company.

So, if you were to examine sales volume over the previous year, you would group the things that accounted for the largest share of your yearly consumption value into category A. Until you reach the value threshold for category A (60–80% of your total value annual consumption), you will keep adding things to category A. After that, you would keep adding stuff to category B until you reached 20%–30% of your yearly utilisation value. Finally, the objects that are left would all belong in category C.

Measure and Re-Assess

After following the steps mentioned above, ABC analysis is formally integrated into your inventory management system. However, it doesn’t end there.

Your items will inevitably evolve. A vendor in the supply chain can decide to transport your products at a higher cost overnight. For some products, your manufacturer could reduce the unit price. The demand may increase or decrease.

Your goods’ proportion of the value of your entire inventory will vary due to these adjustments; therefore, you’ll need to modify your ABC categorization to reflect those changes. However, the last thing you want to do is use an old categorization to classify an item that is currently an A-level item as a C item. Therefore, be careful to review your ABC method periodically.

Suggested Read: When your Business Requires ERP Inventory Management System?

Best Practices and The Most Effective Approach For Applying ABC Inventory Analysis

Applying ABC method of inventory control consistently and reviewing it frequently yields the most outstanding results. The following are some of the best practices to follow while doing ABC analysis in your company:

Categorise Inventory Items in a Simple Way

It is essential to keep your ABC analysis categories straightforward to simplify your inventory management. Your teams should have no trouble identifying which goods fall under a particular category immediately. For instance, popular categorization techniques include using the product’s cost or frequency of sales.

Specify Classification-Based Labour Levels

A labour level, or the number of hours spent working on a particular inventory class, should be allocated to each categorization. Naturally, higher labour levels should be assigned to a classification if it has a more excellent value or influence on the company.

Review Each Class Separately

Each categorization should be evaluated following the guidelines established by the original ABC analysis. This entails a unique set of KPIs, performance evaluations, and a strategy for reordering or offloading any excess inventory. You may learn more here about inventory management KPIs

Review The Categories

The initial ABC study considered several product categories and the company’s current state. It’s crucial to review the existing categories and, if required, reclassify when inventories and markets change. Consider sales changes by product and class, new industry rivals, and consumer trends.

Conclusion

A company may effectively assess the worth of its products by using an ABC analysis. Large volumes of inventory may be managed with this straightforward method, which also determines how many resources should be devoted to each categorization to maximise profits.

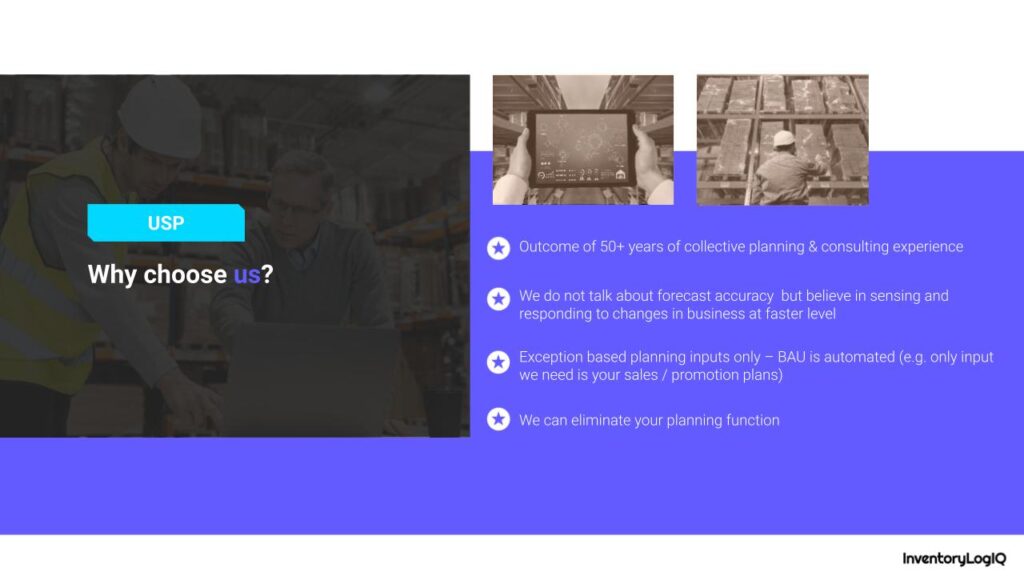

The inventory management procedure may be made even more efficient by using specialised software. For example, a platform for inventory management may gather vital product data, monitor specific product levels in real-time, and boost order processing effectiveness.

Inventory LogIQ is one of advanced inventory planning, and management tools for small, medium and enterprise eCommerce businesses. It enables businesses to leverage hard data and rich insights to streamline the inventory planning operations. A brainchild of WareIQ, which is backed by leading global investors includingY Combinator, Funders Club, Flexport, Pioneer Fund, Soma Capital, and Emles Venture Partner, Inventory LogIQ has intelligent inventory planning capabilities that allow you to manage any change in the market, experience a new & better way of managing your inventory operations.