Importance, Objectives, Uses and 4 Techniques of Inventory Management in Supply Chain Processes in 2023

Inventory management affects the movement of items along the supply chain. An effective inventory control system ensures that the corporation retains just enough stock or raw materials to maintain good manufacturing and market supply of completed products. As a result, a company with a well-functioning supply chain management system can stay competitive in its field. Information technology has benefited inventory management. For example, IT systems can monitor inventory to guarantee that no excess or insufficient stock is stored, improving the firm’s efficiency and lowering operating costs.

Manufacturing companies manage their inventory levels to keep track of raw materials and then manufacture just enough goods for the market to avoid the costs of generating and maintaining surplus inventory. That is why inventory management in supply chain management is essential for the efficient working of eCommerce fulfillment organizations.

- What is Inventory Management in Supply Chain Operations?

- Relationship Between Inventory Management and Supply Chain Management

- 7 Objectives That Emphasize the Role of Inventory in Supply Chain Management Systems in 2023

- 5 Reasons for Inventory Control to be the Initial Step in Supply Chain Management Systems

- How Can You Improve Inventory Management in Supply Chain Management?

- 4 Inventory Management Techniques to Overcome Supply Chain Problems in 2023

- Conclusion: How InventoryLogIQ is the Most Efficient Inventory Management System

- Inventory Management in Supply Chain: FAQs

What is Inventory Management in Supply Chain Operations?

Inventory management in supply chain operations is one of the most crucial components of any organization. It is essentially the management of items or stock, which refers to the goods that a company organization produces at any particular time for selling or manufacturing. The administration must ensure that the commodities are kept at a cost-effective level and that stock is always available. If an organization has too much inventory at any particular time, it will be unprofitable since the cost of holding it will be too high, reducing profitability.

Inventory control is crucial in the supply chain since it is the key to long-term success. Inventory may play the most crucial function in supply networks by balancing demand and supply characteristics. The size of the firm determines how well inventory is managed. The actions taken put a corporation in the position of attempting to strike a balance between meeting client needs, which are frequently impossible to foresee precisely, and keeping an adequate supply of resources and commodities. Strategic plans are commonly used to attain balance in managing inventory.

Carrying cost or holding cost of inventory, replenishment lead time, inventory valuation, asset management, inventory quality management, price forecasting, inventory forecasting, the physical state of the stock, ordering cost of inventory, and the physical condition of the list are all areas of concern for inventory management in supply chain management. One of the goals of managing inventory is to guarantee that the merchant has the information to manage and maintain proper merchandise when placing orders, shipping items, handling them in a variety of warehouses, and keeping other costs in check.

[contactus_lilgoodness]

Relationship Between Inventory Management and Supply Chain Management

Inventory control is one of the most critical aspects of supply chain management because it significantly impacts the company’s profitability. Because one of the main goals of a company is to make money, inventory management in supply chain management is critical because it leads to higher revenues. In addition, this centralized management aims to maximize customer value and provide a competitive edge.

The merchant must first determine inventory requirements before establishing organizational goals. After that, he should be able to maintain a supply chain management system and a report on the inventory status at the end of a financial quarter. The inventory should be compared between actual and expected levels. Furthermore, the management should be able to track inventory movement to guarantee no losses. Finally, using the various reports, the manager should be able to reconcile the inventory balances at regular intervals.

7 Objectives That Emphasize the Role of Inventory in Supply Chain Management Systems in 2023

The technique of coordinating the movement of items and services across several processes and locations is known as supply chain management or SCM. Raw material storage and transportation, work-in-process inventories, finished objects, and end-to-end order fulfillment from origin to consumption are all included. All business activities linked with a company’s procurement, production, distribution, and sales order fulfillment functions are included in SCM.

As a result, it entails managing supply and demand, sourcing raw materials and components, manufacturing and assembly, warehousing and inventory tracking, order processing and management, distribution across all channels, and ultimate customer delivery. Supply chain managers are in charge of creating effective plans and strategies to guarantee that the supply chain is running smoothly.

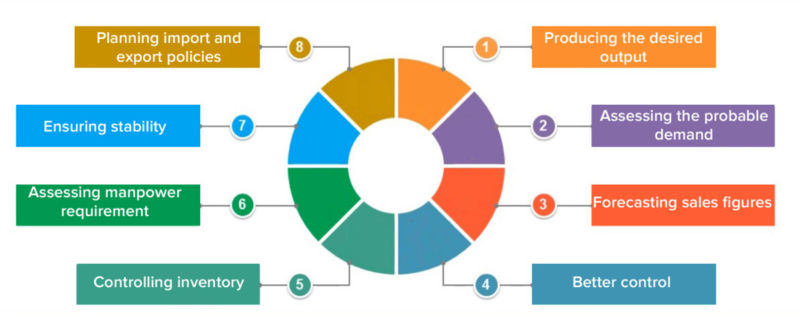

They develop well-defined action plans based on detailed analysis and forecasts, enhancing overall performance. The backbone of today’s business organizations is the ultimate integration of inventory management in supply chain systems. Suppliers who follow SCM principles are anticipated to provide more value to their customers than those who do not. The 7 most important goals of inventory management in supply chain management are listed below:

Improve Operational efficiency

Efficiency is one of the most important goals of Supply Chain Management. Waste minimization is synonymous with efficiency. Waste can take many forms, including squandered materials, squandered funds, person hours, delivery time, and so on. Therefore, waste minimization is an essential aspect of managing the supply chain.

What role can SCM play in waste reduction? First, it manages manufacturing, inventory, transportation, and logistics to reduce waste. This is accomplished by exploring ways to improve systems to reduce waste. If your organization, for example, exchanges inventory data with a supplier and keeps it updated in real-time using ERP software, inventory may be replenished quickly to meet demand. It might be tough to master the process of efficiently managing these operations, but knowing how to do so can be incredibly valuable to your company’s overall performance.

Improve Quality

Waste reduction is only one aspect of inventory management in supply chain management. Another important goal is ensuring the product is of the most excellent quality possible. Quality Assurance is the observance of numerous customer-specified quality parameters, ranging from performance to particular features. This involves following food safety rules, displaying ethical and sustainable business practices, and taking other comparable steps.

Establishing exact criteria and including supplier partners from the beginning is crucial. To keep things moving through the supply chain, you must be nimble in real-time handling modification and variation to that specification. The quality of a company’s goods, as well as its total profitability, are directly influenced by SCM. Quality management in the supply chain is critical for gaining a competitive advantage while minimizing operational costs.

Optimize Logistics

The better the inventory management in supply chain procedures, the better would be the supply chain. However, the purpose of logistics management is to optimize transportation and the supply chain. Each company is responsible for its part in ordering, shipping, and delivering goods in an autonomous commercial environment. Due to bad timing and coordination, the costs of this company model are substantially greater.

Supply Chain Management guarantees that your operations run smoothly and that all stakeholders, including suppliers, manufacturers, wholesalers, and retailers, are on the same page. With SCM, you may optimize transportation and logistics processes with any vendors or buyers you work with. Orders are automatically recorded into a system, alerting other facilities that more resources are needed to complete the request. This ensures that the entire procedure runs smoothly and flawlessly.

Reduce Operational Costs

Efficient supply chain management inventory helps cut off the company’s inventory costs. Building an optimized flow of goods reduces the cost of all forms of company costs, including acquiring, manufacturing, and shipping items. In addition, by facilitating a seamless flow of raw materials between a supplier and a firm and the movement of finished goods between a company and its consumers, the holding period of both raw materials and finished goods may be reduced—this aids in the reduction of losses and the minimization of total operating costs.

Enhance Customer Services

One of the essential aims of supply chain management is customer happiness. By far, the most efficient method of client service is through your supply chain. It directly impacts two of the most critical aspects of customer satisfaction: price and delivery. You can surpass your competitors in terms of the retail price and profitability if you have a well-functioning supply chain. Having high-performing operations also aids you in meeting or exceeding your consumers’ product delivery expectations. It’s vital to keep your consumers happy by giving them what they want when they want it and at the lowest price feasible.

That’s precisely what good Supply Chain Management allows you to achieve. You can give the excellent service, transparency, and visibility that your consumers want by choosing suitable systems, processes, and partners for your supply chain. By building strategies that minimize mistakes and maximize inventory management efficiency, you keep total control over the lifespan of your items, from conception to delivery. The stronger your supply chain is, the better the customer experience will be, the happy your customers will be, and the more likely they will buy from you again.

Streamline Distribution

Supply Chain Management benefits businesses by streamlining the distribution process. Creating adequate coordination between various transportation routes and warehouses is vital to promote faster goods flow. Also, Logistics Management allows companies to reduce logistics costs while delivering goods more rapidly. Consequently, the whole distribution system has been upgraded, allowing items to be delivered at the right time and place. As a result, it’s a good idea to invest in technology that allows you to have efficient logistics inventory management, provide detailed data, automate delivery, give real-time tracking, and conduct other distribution duties.

Establish Coordination

The purpose of supply chain management is to improve coordination among the different stakeholders in an organization. Employees, customers, and suppliers will be able to connect with the firm more efficiently, thanks to establishing a channel. In the case of an emergency, managers may immediately lead their workforce, and employees can contact their supervisors via the established channel. Customers can also access relevant information through self-portals as part of the customer support system. It promotes information exchange among all stakeholders and aids in the creation of a well-coordinated organization.

5 Reasons for Inventory Control to be the Initial Step in Supply Chain Management Systems

Even in our increasingly competitive economy, keeping track of inventory is a virtual necessity because inventory is often a business’ most vital and costly asset for maintaining a centralized supply chain management system. Yet, according to U.S. Small Business Administration, 46% of small firms either don’t track inventories or do so using a manual technique. For five reasons, inventory control should be the initial step in fine-tuning your supply chain management systems. They are listed below:

Improves Inventory Turnover

One of the essential criteria for centralized management is the inventory turnover ratio, which is the cost of items sold divided by the average inventory. A balanced ratio is critical for keeping your inventory profitable rather than squandering money on overstocking, stocking obsolete products, or rushing shipments to satisfy consumer demand.

For example, a low inventory turnover ratio (low cost of goods, high average inventory) means you’re spending too much on items that should have already shipped to customers or were never manufactured in the first place because of the cost of keeping them on the shelves while their value depreciates is counterproductive. High inventory turnover, on the other side (high price of products, low average inventory), suggests you won’t be able to satisfy demand fast if the market shifts.

Allows Capital to be Released

Once you’ve paid for the supplies you’ll need to make your inventory, that money won’t be available until you’ve received payment from a buyer – in other words, your capital is tied to the prospect of a sale. This may restrict you from using that money to put back into your firm or recruit new personnel, among other common tactics for improving revenue development, unless your organization has a quick cash conversion cycle. Inventory control includes making sure that inventory isn’t put into production until you know it will sell rapidly.

Improves Customer Service

Customers should be satisfied with a well-made and rapidly delivered product, which is the expected outcome of a lean and efficient supply chain. An optimized inventory and supply chain results in fewer shipments to complete orders, real-time tracking of orders from the warehouse to the customer’s front door, accurate inventory that prevents charges from being placed on out-of-stock items, and a lower return rate because customers have fewer issues with their product. Swiftly and adequately resolving a customer’s concern will go a long way toward boosting your reputation and assuring future business.

Advances Technology

Inventory control used to entail spreadsheets and manual audits, which were prone to human error and left businesses vulnerable to accounting errors that put them in financial and legal jeopardy. Across many industries, automated and integrated technologies are becoming the norm. For example, financial data, such as accounts receivable, is increasingly combined with sales information, including client histories. The idea is to keep inventory under control from quarter to quarter so that it does not affect the bottom line. That type of real-time data integration wasn’t conceivable until recently. Still, inventory control solutions are now built from the ground up to handle these functions, which helps centralized supply chain management systems run more efficiently.

Encourages Growth Trends in Optimizing Supply Chain Processes

Future trends are increasingly becoming a reality for organizations of all sizes, from cloud computing to real-time tracking. Automated inventory control is the ideal approach to connecting with technologies that will keep you one step ahead of your rivals. “Just-in-time” inventory, for example, can help improve turnover rates by allowing you to retain inventory levels just high enough to meet demand. Businesses require strong ties with suppliers via common software databases to execute “just-in-time” operations like supplying customizable packaging. This will allow order fulfillment to your locations as needed.

Many interrelated yet separate pieces work together to generate customer happiness and higher income in a complex supply chain. Our supply chain is exposed to several variables out of our control in today’s often-disrupted business environment, including fluctuating market demand and new competitors. Our inventory is the one thing we can control: where it is, where it is going, and what we need to do to keep it at growth-friendly levels. Inventory control is the first stage in maintaining an effective supply chain. It may also be the most crucial step, given that poor management and lack of planning are two primary reasons small businesses fail.

How Can You Improve Inventory Management in Supply Chain Management?

Technology is at the heart of effective supply chain management. Traditional, frequently manual procedures are eliminated, saving time and lowering the chance of mistaken addition. In addition, any information captured becomes easier to communicate throughout a complete supply chain when activities are managed digitally. You’re halfway to comprehensive supply chain optimization if your organization has installed a transportation management system (TMS).

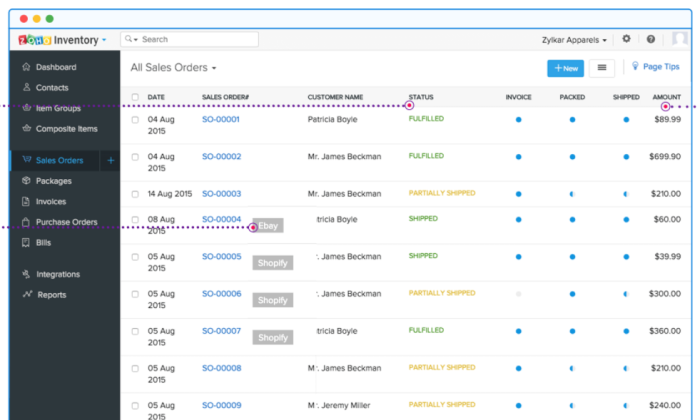

Transportation and logistics inventory management are two critical components of a successful supply chain. Transportation management systems handle product movement along the supply chain and offer a robust communication platform for carriers, shippers, and manufacturers. The amount and kind of items in an eCommerce warehouse or other storage facility are the subjects of inventory management platforms. These pieces of technology, when combined, establish the foundation for businesses to get their products into the hands of customers as quickly as feasible.

When a corporation uses a centralized supply chain management system to respond promptly to a customer’s order, for example, merchandise travels quickly out of the warehouse and no longer occupies inventory space. That space is then freed up for newer goods to take their place. Quick shipments may be handled via inventory management systems, guaranteeing that the oldest product is dispatched first. When inventory and supply chain management operate together, tracking ruined or damaged inventory is more accessible. Products may be tracked down to the SKU level and readily traced as they leave the warehouse. When a product is recalled, inventory management teams have the information they need to locate and isolate faulty merchandise.

Specific transportation management systems, such as Microsoft Dynamics, can link directly with ERPs. When these technologies are combined, logistics professionals benefit from enhanced shipping accuracy, considerable time savings, and access to valuable data for SKU-level cost allocation. Additionally, by exchanging data between systems, integrations between a TMS and an ERP may assist in bridging the gap between logistics inventory management and transportation management, ensuring that all parties involved have reliable, real-time inventory information.

4 Inventory Management Techniques to Overcome Supply Chain Problems in 2023

From the procurement of raw materials to the delivery of the item to the ultimate consumer, the supply chain tracks products. As a result, supply chain management encompasses various components and factors, including logistics for moving resources and goods from point A to point B. Inventory management may be considered part of a more extensive supply chain system.

Ordering, storing, and distributing goods are all aspects of inventory management in supply chain processes. Logistics inventory management, when done correctly, may have a substantial positive impact on a company’s bottom line. On the other hand, poor inventory management decisions, such as over-or under-ordering, may be costly and detrimental to a company’s long-term health. If a company does not spend on learning and adopting the best logistics inventory management practices, supply chain interruptions will increase dramatically. There are vital concerns that have led to supply chain challenges.

One is the worldwide supply chain crisis linked to the COVID-19 outbreak has received the most significant attention. Worldwide, suppliers have been impacted by safety limitations, labour shortages, and shutdowns. Some supply chains have only had minor glitches, while others have yet to recover and return to routine fully. The good news is that you and your firm can overcome these supply chain disruptions by employing a few proven, contemporary inventory management solutions. They are listed below:

Utilizing Automation, Artificial Intelligence and Machine Learning

Automation is a fantastic technique for improving the efficiency of inventory management in supply chain processes. Warehouse automation, for example, may increase productivity by directing robots to discover or transport products using cloud-based technologies. As a result, individuals no longer need to locate and package products. Essentially, these robots may support human employees by acting as assistants and increasing the overall pace of operations within a company. Automation technologies powered by AI and machine learning can also help with supply chain difficulties. The programme may gather and interpret data to make the supply chain as a whole more visible.

Taking Advantage of Inventory Control Applications

The more inventory management in supply chain processes you have, the less disruption and stress the rest of the supply chain will give you and your company. While achieving the appropriate degree of inventory control isn’t always simple, many businesses use logistics inventory management methods like the ABC analysis to make the process go more smoothly. All goods are designated as A, B, or C in an ABC analysis. The highest demand or value is for A-level items. C-level items, on the other hand, sell slowly and are counted seldom. B-level things fall midway in the middle. Inventory and supply chain managers can better assess whether to purchase replacement stock once goods have been categorized this way.

Using Both Passive and Active Demand Forecasting Techniques

It makes economic and logistical sense to know how much of a product to have on hand each quarter. However, predicting demand for a particular product may be challenging, which is why many people divide demand forecasting into passive and active demand forecasting approaches. Active demand forecasting entails keeping a close eye on what’s going on in the market. It’s a combination of intuition, trend data, and historical data. Because they have limited historical data to evaluate, startups often rely on active demand forecasts for advice. Historical patterns are used in passive demand forecasting to predict future requirements. Companies can choose between passive and active demand forecasting or a combination.

Employing Inventory and Warehouse Management Software

If you go into any company for inventory control and good supply chain management techniques, you’ll see a lot of technology. The warehouse management software system has been a game-changer for smoothing out the creases of inventory management in supply chain processes. The majority of warehouse management systems collect significant amounts of data. They also indicate what’s going on in the warehouse and the whole supply chain. This makes them essential in identifying possible supply chain disruptions and pain areas.

There are several other advantages to using warehouse management software. Many work in tandem with other business systems, such as customer relationship management software. That implies that when a customer cares professional answers the phone, they may leverage warehouse management information to give excellent service. It’s hard to outsmart every supply chain snag, especially in the face of uncontrolled occurrences like a worldwide epidemic. Nonetheless, best practices and tools can help mitigate the impact of interruptions in inventory management in supply chain processes.

Suggested Read: What is Supply Chain Forecasting?

Conclusion: How InventoryLogIQ is the Most Efficient Inventory Management System

Supply chain management is an integral part of every business’s operations. It is critical to assist a company in gaining a competitive edge and maximizing customer satisfaction. Because of the increased degree of competitiveness, a company’s supply chain management function has grown increasingly significant in today’s corporate environment. As a result, there is a more critical requirement for businesses to assure consumer satisfaction. Inventory management, the backbone of supply chain management, is vital to customer satisfaction. Inventory management, through EOQ and JIT, aids in the reduction of supply chain management expenses as well as the forecasting of inventory levels.

Furthermore, inventory management is a valuable strategy for managing risk in an organization by ensuring that safety stock is maintained. Supply chain management can fulfill its most fundamental goals through inventory management. As a result, it may be claimed that inventory management lies at the heart of supply chain management and that organizations must embrace it if supply chain management is to be successful. In other words, without inventory management, businesses will struggle to prosper in the supply chain. It serves as the foundation for all other supply chain operations, including transportation, production, and distribution.

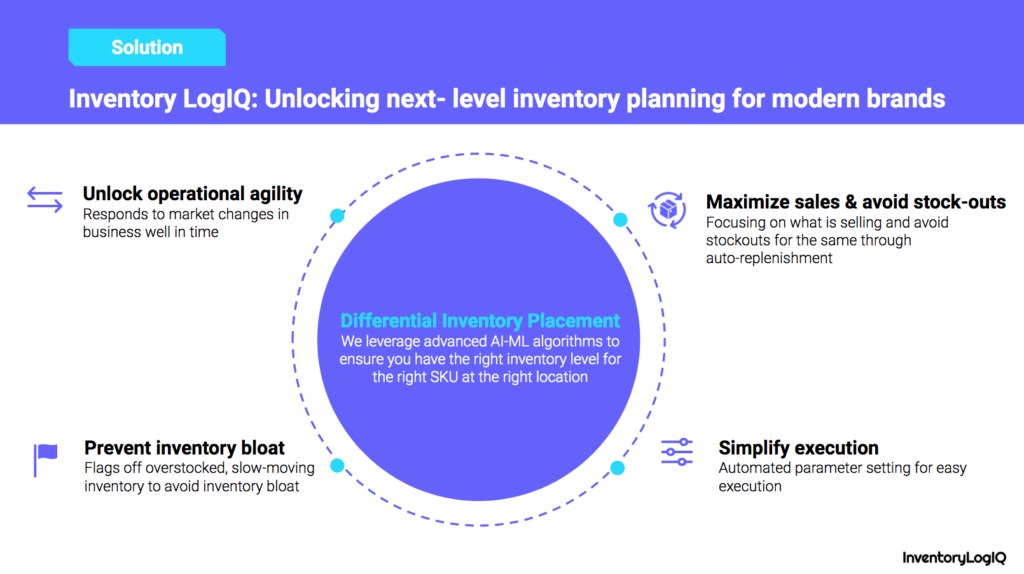

InventoryLogIQ is a leading inventory management company that specialises in managing the supply chain of online and offline businesses through effective inventory management. We can help your company improve its inventory management in supply chain processes in the following ways:

- Through automatic replenishment suggestions, InventoryLogIQ’s inventory planner aids in demand forecasting and maintaining precise stock levels across SKUs in warehouses in appropriate locations.

- Checklist-based Quality Checks are also conducted by InventoryLogIQ’s operations professionals, guaranteeing that the QC process is complete and dependable.

- We use handling units to convey merchandise and scan bar codes for pick and pack fulfillment services.

- We help design and implement of a process for tracking and tracing misplaced merchandise.