Retail Inventory Management Guide: Meaning, Benefits, Latest Strategies, and 10 Best Practices to Follow in Retail Inventory Method in 2023

Inventory is one of, if not the most important aspect of every retail business. It is the means by which you are able to sell products to customers in exchange for monetary compensation and is the key method that businesses use to break even and eventually become profitable. However, it is not advised to just keep unspecified quantities of inventory on hand at all times. Inventory management is crucial to the successful running of any business as it reduces storage costs, operational costs, fulfillment durations, the time taken to pick, pack and ship inventory, and much more.

Having a comprehensive inventory management procedure in place will also ensure that your business is running at its most efficient capacity while also enabling you to store the accurate amount of inventory for specific occasions. In this blog, we will discuss what retail inventory management is, its importance to retailers, best practices to follow, and the steps involved in implementing it smoothly.

- What is the Meaning of Retail Inventory Management?

- Primary Benefits of Using a Store Inventory Management System

- 5 Latest Strategies to Capitalize on the Success of Your Retail Inventory Method in 2023

- 10 Best Practices to be Followed in the Management of Retail Inventory in 2023

- Have Consolidated Records for Important Product Details

- Assign Scannable Codes to Every Product

- Integrate Sales With Inventory Data

- Conduct Product Checks at Regular Intervals

- Have a Purchasing Pipeline in Place

- Implement a Specific Stock Receiving Process

- Prepare Strategies for Having Special Promotions

- Have a Strategy for Handling Stranded, Excess and Dead Stock

- Create a Plan for Dealing With Returns

- Provide Visual Cues to Help Staff Identify Products

- Conclusion: Streamline Your Retail Inventory Management With InventoryLogIQ

- Retail Inventory Management: FAQs

What is the Meaning of Retail Inventory Management?

Retail inventory management consists of all the procedures involved in ensuring that your business always has the right amount of inventory at the right time in order to successfully meet customer demand. The ills of improper inventory management can result in overstocking, understocking, confusion relating to orders, and much more, which can cost your business in terms of money, reputation and wasted inventory.

Having a detailed store inventory management system is key to the way businesses are able to store their inventory and fulfill orders to customers. Retail inventory management is useful because it provides insights into many different metrics pertaining to multiple aspects of the business. Some of them are listed below:

- Storage locations of each SKU

- Number of units of each product

- The success of each item based on demand

- Profit margins generated by each product

- The accurate amount of inventory to store

- Replenishment points for specific SKUs

- Discontinuation of unsuccessful products

- Sales patterns according to season

- Important items to prioritise

- Inventory data according to each sales channel

Primary Benefits of Using a Store Inventory Management System

Improved Efficiency

Retail inventory management allows retailers to track inventory levels and product data in real-time, which can help reduce the time and effort required to manage stock. This also allows for a better flow of information and products throughout the supply chain. Whenever an order comes in, the first process that needs to be conducted is to locate the relevant product package and dispatch it. If this process can be done seamlessly, it will bode well for the ultimate fulfillment of that product.

Increased Accuracy

By automating inventory tracking, retail inventory management systems can help reduce errors and improve accuracy in inventory counts. You can also forecast inventory for future sales and set a budget for marketing, product development, and recruiting using the inventory you currently have in combination with previous sales data. This will ensure that products are stocked in suitable quantities for different times of the year and will help your business fulfill orders faster and more accurately.

Enhanced Customer Satisfaction

By ensuring that products are in stock and readily available, retail inventory management can help improve customer satisfaction. This is because every process relating to order fulfillment, starting with shipping products from the warehouse to delivery to the customer’s doorstep, happens more seamlessly if every process involved is streamlined. This contributes to a positive overall experience for the customer and increases their chances of making repeat purchases and spreading the message to their friends, family, and colleagues.

Better Loss Prevention

Retail inventory management systems can help retailers identify and prevent inventory shrinkage, which can result in significant financial losses. Additionally, because inventory will always be stored at optimum levels, the amount of inventory at risk of being damaged, becoming obsolete, or getting expired will be significantly lessened, reducing the wastage of money-generating SKUs. You can save on storage expenses and avoid tying up your cash flow with dead goods when you always have the right amount of inventory available.

Heightened Data Analysis Capabilities

Retail inventory management systems often come with built-in reporting and data analytics tools that can help retailers make informed business decisions. Whether you want to forecast future demand levels for certain SKUs, identify patterns by viewing historical data from previous sales cycles, or ascertain the performance of different types of products, retail inventory management will provide you will all the information you need to never be kept in the dark regarding the success of your business and its inventory.

5 Latest Strategies to Capitalize on the Success of Your Retail Inventory Method in 2023

Utilize an Inventory Management System

If you’re still performing retail inventory management manually, you may need to upgrade to a dedicated inventory management solution to help automate various important processes. This will not only speed up and optimize operations but will also reduce the time, effort, and mistakes made by doing them manually. These advanced technology-based solutions can conduct a variety of tasks, such as tracking inventory across fulfillment centers and sales channels, providing historical performance data for specific seasons, automating picking and packing, forecasting future demand, and much more.

Implement ABC Analysis

ABC Analysis assigns value to your items based on their demand by separating them into 3 categories. “A” will consist of your most sold and well-regarded items that need to be replenished on a constant basis, “B” will comprise your more mid-range products that may also be expensive but need to be stocked less frequently such as on a monthly basis and finally, “C” will make up the products that are slow-moving or are seldom demanded and hence they can be ordered only when stocks become critically low. Organising your inventory into these categories will streamline your management procedures and make it easier to identify various products in storage.

Assign Minimum Order Limits for Each SKU

Minimum order limits are the thresholds assigned to each product to ensure that the minimum quantity of that particular item is always present in storage to account for any unforeseen scenario or unaccounted-for demand. Having these limits in place will ensure that you are always in the position of fulfilling an order, which will prevent customers from having a negative experience. It will also help you capitalize on every order that comes in so you can maintain your profit margins and not let any demand go to waste. The formula to calculate the minimum stock threshold for each individual SKU is mentioned below:

Minimum Stock Threshold = (Average Daily Product Sales ÷ Number of Working Days During That Month) x Average Product Delivery Time

Strengthen Relationships With Your Suppliers

Since inventory is one of the most important assets for any eCommerce and brick-and-mortar store, suppliers deserve to be given the highest importance since they are the ones who manufacture the goods your business eventually sells to turn a profit. Keeping your vendors close and being in their good graces is important for multiple reasons. In addition to making it easier to keep them in the loop about order information, it can also help you be on the same page regarding revisions in product quantities needed, more concisely understanding when orders will be received and taking advantage of bulk discounts, resulting in a more transparent and efficient supply chain overall.

Track Relevant KPIs

Key performance indicators or KPIs are trackable metrics that provide important insights into particular functions of your business. They are especially important for retail inventory management as monitoring and analysing KPIs such as your inventory carrying cost, demand for each SKU, sales per product category, inventory turnover rate, and more can help you make well-informed decisions regarding restocking your inventory, how much to order for particular situations and assessing the performance of various processes so you can identify any bottle in your store inventory management system.

10 Best Practices to be Followed in the Management of Retail Inventory in 2023

Have Consolidated Records for Important Product Details

Having the most important information about all your SKUs easily accessible and consolidated together will make locating and packing products much faster and simpler. Products generally come labelled with multiple details, but it is imperative to include a record of the most important ones pertaining to each specific SKU. Some of these details include:

- Item name

- SKU number

- Brand information

- Product dimensions

- Manufacturer details

- Total cost

- Minimum reorder quantity

- Units on hand

- Reorder duration

- Economic order quantity

Assign Scannable Codes to Every Product

For sellers that sell a variety of products and variations, it can get confusing storing and identifying inventory, especially if it is across multiple storage locations. A simple way to mitigate this and improve your retail inventory management is to assign scannable bar codes to every item in storage and use code scanners to instantly identify products and get their details.

This provides a degree of automation and control to your inventory identification procedures and will help keep your storage facility more organized.

Integrate Sales With Inventory Data

Data on sales and inventory can be combined using a retail inventory management system. It will help you determine which products are selling the quickest and which ones are moving slowly in terms of sales velocity.

Utilize the product data to choose how much and when to place reorders, as well as when to run specials or discounts. Additionally, doing this will also help tidy up your product records and have all the information pertaining to sales and inventory levels, across storage locations and selling channels, in one place.

Conduct Product Checks at Regular Intervals

To make sure your inventory is accurate, you should periodically count it. To prevent mistakes, account for shrinkage, damage, faults and returns. A retail inventory management system simplifies this process because you don’t have to start from scratch; you just need to double-check your data. So, you can concentrate largely on deviations.

The complexity, size and type of software solution you employ will influence how frequently counts are performed in your firm. But at the very least, experts advise counting having inventory counts every quarter or year depending on the scale of your inventory.

Have a Purchasing Pipeline in Place

To ensure that you don’t fall behind seasonal patterns or run the danger of running out of stock, schedule periods to evaluate your purchase data and arrange orders accordingly. You can configure an electronic system to send reorder alerts based on the stock levels of specific products. These levels ought to include a safeguard that enables normal sales to continue.

Check which items are out of stock or nearing reorder points if you’re using a manual system, then add them to your shopping list. Prioritise an item’s purchasing plan based on an item’s profitability, popularity and lead time. Having a specific process to follow for every purchase will help improve various functions of your retail inventory management.

Implement a Specific Stock Receiving Process

If you have a specific strategy in place, you can check incoming orders and accurately input the commodities into an inventory system during the receiving process. Any product damage or deterioration caused by your supplier during transit can cause issues, including unanticipated stock shortages, payment increments and the accumulation of dead goods.

Verify the contents of every pallet you receive against the purchase order details to ensure there are no disparities. Follow up with suppliers regarding any problems. After that, add the items to your inventory count and place them in storage. The simplest method of controlling inventory is perpetual inventory management, which entails counting products as soon as they arrive.

Prepare Strategies for Having Special Promotions

For a variety of causes, such as an economic downturn, obsolescence or seasonal variables, product sales may fall short of expectations. If you do provide markdowns, use restraint while reducing prices and relocating slow-moving merchandise so that space can be made for more lucrative goods.

Additionally, plan your advertising approach in advance to make sure you have adequate inventory available that is ready to meet demand. It is important for every business to turn demand into a sale and ensuring that items can be sold, even at slightly reduced prices, will have a positive impact on your retail and inventory management and business as a whole.

Have a Strategy for Handling Stranded, Excess and Dead Stock

Overstocking inventory drains capital and reduces profitability. Dead stock comprises products that are associated with faulty deliveries, transitory damage and low demand during specific seasons. Items that fit this category should be noted and then suitably removed from your storage. Establish a procedure for dealing with dead, excess and stranded inventory and conduct it on a regular basis.

Send pullbacks or goods you can return to suppliers for credit, as soon as possible. Make note of any return shipment deadlines. According to their policy, suppliers should be informed and given back damaged or defective products immediately. You can take care of the leftovers by selling them to outlets, recycling or disposing of them or selling them at highly discounted rates, depending on what is the best option for your business.

Create a Plan for Dealing With Returns

Returns are an inevitable prospect for every retailer, regardless of whether they sell offline or online. Without a system in place to handle client returns, you run a higher risk of holding onto unsold inventory or skipping the chance to relist a purchasable item.

When a consumer returns an item, examine it to see if it is broken or defective and then send it back to the vendor, fix it or write it off as you see fit. If the item is marketable, include it in your inventory counts and store it suitably. Following a similar procedure whenever returns are initiated will help you quicken and streamline your retail inventory management.

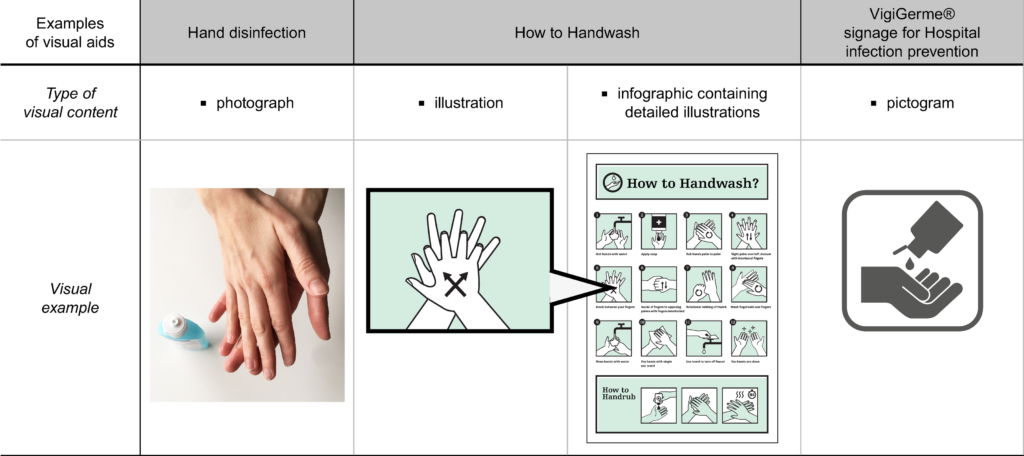

Provide Visual Cues to Help Staff Identify Products

Providing visual assistance to your staff can enhance the ease and pace with which items are able to be identified and prepared for dispatch. Having images of the products alongside their information can be exceptionally helpful for retailers that deal in a variety of items and brands.

It gives your staff a discernable sense of the look and characteristics of the item they are looking for and accounts for any inexperience involved in carrying out this task, helping to reduce the scope and frequency of unwanted errors relating to picking, packing and shipping products. Your staff will be better equipped to carry out locating inventory if they have additional assistance in the form of rich content.

Conclusion: Streamline Your Retail Inventory Management With InventoryLogIQ

Conducting competent retail inventory management should be prioritized by every online and offline seller. Retail inventory management can have numerous benefits for retailers. It can help improve efficiency, increase accuracy, enhance customer satisfaction and reduce losses due to shrinkage. It also provides retailers with valuable metrics and insights that can enhance the effectiveness of every business decision.

Additionally, it prevents businesses from making misguided decisions pertaining to inventory replenishment, storage, order fulfillment and much more. Overall, retail inventory management is an essential component of any successful retail business. If you need assistance with improving the retail inventory management of your business, consider partnering with InventoryLogIQ.

By giving our partners all the tools they require to precisely forecast future demand, determine the storage levels of each product based on different metrics, automate replenishment triggers to curtail stockout situations and much more, InventoryLogIQ specialises in inventory optimization and management. We are able to support your company in the following ways:

Increase Your Operational Capability

We assist you in forecasting events and conducting inventory analysis by using tools like ABC inventory analysis and others, so you can set up your business appropriately.

Reduce Inventory Stagnation

We assist you in identifying items that have been overstocked and suffer from low demand in order to prevent the bloating of certain SKUs in your storage facility,

Boost Sales Velocity

We help you maintain optimal levels of high-demand SKUs and highlight successful products so you can always keep them stocked.

Improve Operations

We offer a variety of automations that can improve many aspects of your inventory management procedures.

Place Your Inventory Correctly

We help you take advantage of modern AI and ML algorithms to make sure the appropriate amounts of inventory are kept in the most suitable places.

Suggested Read: What is Retail Replenishment?