Inventory Allocation 101: Definition, Pros, and Cons & Factors to Consider While Allocating Inventory in eCommerce [2023]

Inventory is the key asset of any eCommerce company to be able to transform an order into a delivery. One of the main ways to ensure that this process is carried out efficiently is proper inventory allocation. This enables companies to place the appropriate amount of inventory at every step of the supply chain process, to mitigate shortages and unforeseen circumstances. We will be discussing what inventory allocation is, inventory allocation methods, reasons for companies to employ an inventory allocation strategy, and factors to consider when making that decision.

- What is Inventory Allocation?

- 2 Types of Inventory Allocation Methods

- Advantages and Disadvantages of Inventory Allocation

- Why Should eCommerce Companies Have an Inventory Allocation Strategy?

- 4 Factors to Consider While Allocating Inventory in eCommerce in 2023

- How Can InventoryLogIQ Help With Inventory Allocation?

- Conclusion

- Inventory Allocation: FAQs

What is Inventory Allocation?

The process of strategically optimising and tracking the levels of inventory that an eCommerce company maintains across its entire distribution network (including multiple sales channels and fulfillment centers is called inventory allocation.

Let us look at a typical, growing eCommerce company that sells its products across multiple online channels, including Flipkart, Amazon, Shopify (etc.), and needs to allocate its inventory to each channel based on the volume of orders received. To achieve the shortest possible delivery time, the eCommerce firm will use multiple fulfillment centers and warehouses to fulfill orders. Given this scenario, the firm must utilise various inventory allocation methods to fulfill orders based on the optimal mix of products, customer orders, and warehouse locations.

An optimised inventory allocation exercise ensures that the correct inventory levels are maintained at each fulfillment location, so customers’ orders are delivered at the earliest possible time. Sudden increases in demand such as during a flash sale, are also built into the calculations.

2 Types of Inventory Allocation Methods

Let us look at the two most prominent inventory allocation methods that are used:

Manual Inventory Allocation

As the name suggests, if an eCommerce firm uses physical spreadsheets, and inventory ledgers and analyses data manually for inventory allocation, it is referred to as manual inventory allocation.

Unfortunately, not only is this method time-consuming but it is also prone to miscalculations, errors and other inefficiencies. A primary concern is that when a business grows, the problems multiply rapidly and manual inventory allocation can often compound those problems by creating more mistakes which can have disastrous consequences.

Tech-Enabled Inventory Allocation

Most modern inventory allocation methods are enabled by eCommerce firms investing in the latest technologies that seamlessly manage and track their inventory and its movement across their entire distribution network.

By using electronically-captured data and the deep insights they offer, this method of inventory allocation is done in real-time and maintains high levels of inventory accuracy and efficiency while being easy enough to use. Businesses primarily employ inventory management software that consists of all the above features which help businesses automate their inventory allocation procedures.

Advantages and Disadvantages of Inventory Allocation

Advantages of Inventory Allocation

Avoids Overstocking

The perils of overstocking are many, often with disastrous results which can be especially pronounced for eCommerce startups or small firms. To begin with, overstocking causes overutilization of warehouse space clogs up invaluable cash flow, and increases carrying costs.

Additional problems include high insurance premiums, rent, and labour. Problems of expiry dates, damage, and pilferage/theft also start cropping up for inventory that stays on the shelves for long periods of time without being shipped out. Inventory allocation helps prevent overstocking by making businesses aware of the optimum amounts of inventory they require.

Helps in Order Fulfillment

Conversely, very low stock levels cause their share of problems. Firms would run short of inventory and be unable to capitalise on customer demand. Even worse would be the issues of sudden stock-outs, especially when you may have already confirmed customer orders. All this would drive your customers to your most feared result, i.e. you would lose them to competitors who provide more efficient service.

About 3/4th of today’s online customers would be unlikely to return unless their orders are fulfilled within 2-days. Efficient inventory allocation would eliminate such problems by helping firms ascertain the exact amount of inventory they would need.

Assists in Understanding Buyer Behaviour

A huge benefit of efficient inventory allocation is that it helps to understand the buying behaviour of your customers. By tracking data, clustering them into ACV-cohorts, and analysing stock movement across important parameters, firms can learn much about their customers’ buying habits and preferences. Ultimately, this enables management to make better business decisions.

Disadvantages of Inventory allocation

Lack of Proper Usage

Poor inventory allocation methods that are not tailored specifically to your business can set you up for failure. Therefore, the goal is to make the correct and informed decisions to be able to efficiently manage and allocate inventory, not just to simply adopt an inventory allocation process to be up to speed with the rest of the industry.

Struggles to Adapt

Oftentimes, companies are led by pure profitability and only maintain high-profit and high-demand items. If customers decide to change their preferences suddenly, you could be left with dead stock. You would be precariously placed since you would not have left enough warehouse space or invested in SKUs for other customers (that offer less profitability).

Why Should eCommerce Companies Have an Inventory Allocation Strategy?

We live in an age of information and as you would have heard, knowledge is power. Awareness about your inventory requirements, broken down by locations, nature of products and other factors, the type of SKUs, customer clusters, and their preferences, and a deep understanding of buyer behaviour gives you this knowledge. With it, you can improve your decision-making through timely and informed decisions while also forming the bedrock of optimising your supply chain.

Modern eCommerce firms are prone to fluctuating inventory levels which is an underlying result of selling across multiple channels and different locations. Using modern inventory management software and technology enables eCommerce management teams to stay ahead of the curve and maintain close working relationships with their 3PL partners and fulfillment teams.

After all, an effective inventory allocation strategy will reduce operating costs, maximise inventory ROI and successfully satisfy customer demand. Let’s look at the 4 key reasons to have an inventory allocation strategy:

Prevents Overstocking

Firms often adopt the easy way, i.e. to stock more inventory than they expect, just in case they fall short. However, that is often counterproductive to company profitability and cost-efficiency. On the contrary, overstocking drives up inventory carrying costs, requires larger warehousing facilities, requires more labour and higher insurance, and creates problems of pilferage and dead-stock – the list is endless.

Optimising your stock levels by following a robust inventory allocation strategy based on comprehensive data analysis, demand trends, and SKU movement is the way to go to prevent overstocking.

Avoids Overselling

A robust order pipeline is an aim for all eCommerce companies. However, it requires significant study and projections based on analyzing the correct parameters. Overselling leads to backorders and results in a poor customer experience, delayed shipping, price fluctuations, etc.

The correct inventory allocation strategy to prevent overselling is for it to stem from your demand analysis. Therefore, it becomes imperative to maintain data about seasonality, promotions or sudden changes in the ecosystem (e.g. a competitor going bust and their orders suddenly shifting over to you). This prepares firms to stock the correct inventory levels (with requisite safety buffers) based on past trends and future growth projections.

Optimises Management of Multiple Channels

Modern retailers have adopted an omnichannel strategy to satisfy changing customer preferences and demands. However, along with its advantages, it also needs an efficient omnichannel inventory allocation strategy to tackle stock level oversight, order returns, reorders, and stock forecasting problems.

Using inventory management systems that track the demand and supply of stock across an omnichannel network is of great help. Popular eCommerce platforms offer direct, API integrations with your MIS to help you track inventory movement from a centralised dashboard, across multiple platforms, which makes the entire inventory allocation process faster and more efficient.

Assists in Scaling Business Operations

Extending the point above, it will become impossible to scale if eCommerce firms don’t implement modern tech stacks and processes that enable better decision-making to run the business.

However, this can be daunting, given its costs, knowledge requirements, and time constraints. Therefore, eCommerce firms can partner with 3PLs (third-party logistics companies) to take care of the rising need for order fulfillment and inventory management.

A 3PL brings significant capabilities across an extensive network of fulfillment locations, logistics capabilities, and technology – these are must-have features as a firm begins its journey of growing its customer base and expanding its services.

4 Factors to Consider While Allocating Inventory in eCommerce in 2023

You may sell hundreds of SKUs via an omnichannel sales network or use multiple warehouses for order fulfillment. You could be a niche brand selling to a limited number of customers or an eCommerce startup just getting started with limited monthly orders. You may even be a behemoth fulfilling thousands of daily transactions across the globe. Establishing a solid inventory allocation policy is the cornerstone of achieving supply-chain efficiency and successfully servicing your customers, regardless of your status.

Let’s look at the key factors to consider during inventory allocation:

Demand for Inventory

Perhaps, the most important tool for an eCommerce business, especially a growing one, is the demand forecasting function. It creates a ripple effect throughout the organisation whereby you can make well-informed decisions around production, promotion, labour, and much more.

While it is true that you will unlikely ever achieve 100% accuracy with demand prediction, if you set up the correct procedures and use advanced tools and technology that are available, you should have an accurate enough handle on your sales patterns.

Adopting a data-driven methodology will enable firms to make sound inventory allocation decisions and accurately predict the amount of inventory required to be stored across their warehouse locations and how much must be allocated to different sales channels, depending on demand. Strong demand-forecasting techniques also consider promotion-led demand, flash sales, seasonality and other temporary peaks and valleys in demand that will directly impact inventory allocation.

Availability of Inventory

Evolving customer preferences have meant that delivery times are an increasingly important element for a business to differentiate itself from the competition. Studies show that customers rarely return to an online platform if their order fulfillment experience isn’t satisfactory.

A crucial part of this is achieved by ensuring that the correct mix of inventory and supply is maintained at shipping destinations closest to the customers’ addresses.

Modern inventory tracking software is a useful tool that ensures accuracy and visibility. These highly sophisticated systems allow you to aggregate demand patterns across channels and locations, thereby allowing you to aggregate the appropriate inventory levels that must be maintained at every warehouse location. In turn, this helps in setting reorder levels, organizing transportation, hiring labour (both full-time and part-time), and negotiating rates with suppliers, to name a few. Additional benefits include not having to urgently fulfill orders from warehouses further away from the delivery address due to a stock-out at the nearest one.

eCommerce firms typically use automated stock-tracking systems that let them seamlessly connect to vendors, suppliers, and other supply-chain stakeholders via a centralised cloud-based system. Therefore, all critical data points like SKUs, channel throughput, inventory availability at fulfillment centers and customer details are available holistically and easily.

Availability of Warehouse Space

Another important factor to keep in mind while planning your inventory allocation is the available warehouse space, the cost of renting it, and operating costs.

eCommerce firms partner with 3PL firms so that they have access to their vast network and resources of warehouses, on-site teams, transport fleets, and modern operating systems. Based on your requirement, storage fees will vary from a fixed fee per pallet, square meters allocated, according to SKU, the transaction (etc.)

The simplicity of Order Fulfillment

As mentioned earlier, an efficient inventory allocation process shortens order delivery times; simplifies logistics and saves costs.

To ensure the shortest possible delivery times, you must minimize the shipping zones a parcel needs to travel to reduce last-mile delivery costs and the time taken to deliver it. This is achieved by maintaining sufficient stock levels at all warehouse locations across the entire network of warehouse/fulfillment centers that you operate. For example, suppose you anticipate an uptick in sweaters and warm clothes in northern India just before the onset of winter in November, you should allocate additional inventory there so that they can be delivered faster and with minimal distances travelled.

How Can InventoryLogIQ Help With Inventory Allocation?

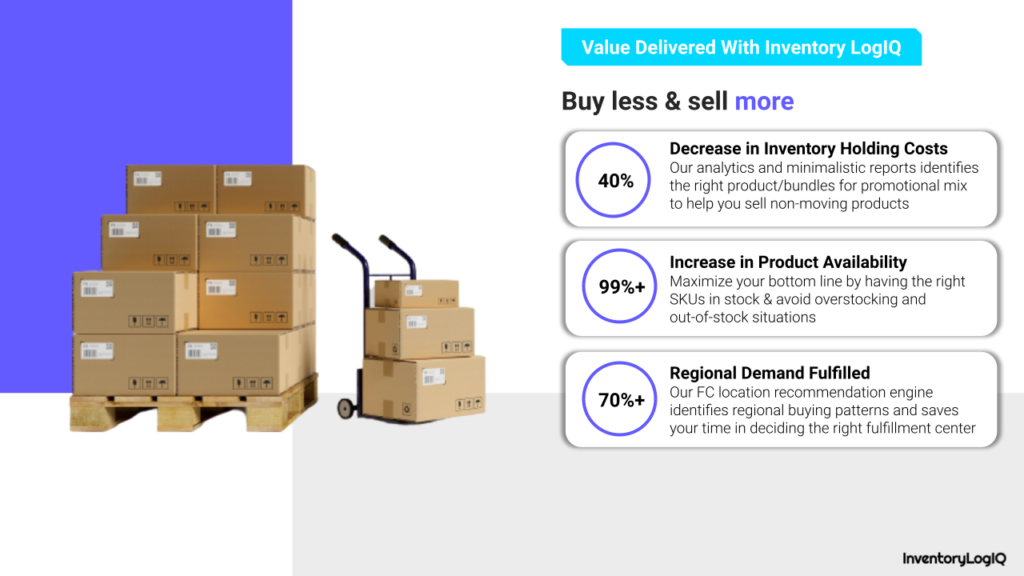

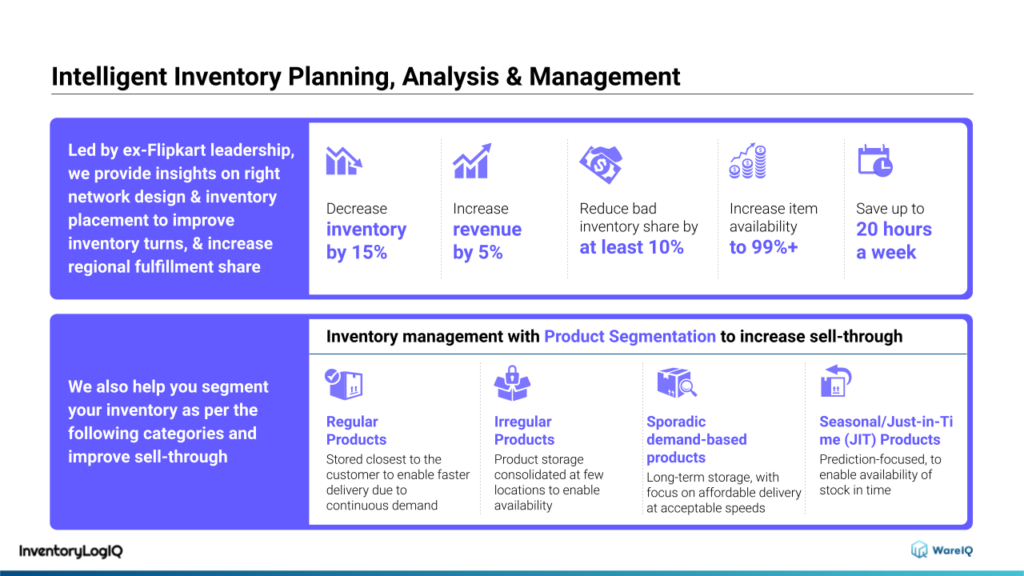

InventoryLogIQ can assist clients with inventory allocation by deploying their significant capabilities in the field. Let’s look at some leading ones:

Automating Inventory Allocation

With its modern automated technology, InventoryLogIQ provides its users with a centralised dashboard that gives clients a bird’s-eye view of the entire operation, across all platforms. This provides a detailed and accurate view of inventory movement, including tracking at the SKU level, cluster viewing broken down by sales channels, unit type, storage locations (etc.). This is a critical tool in managing your inventory allocation.

Streamlining Inventory Management

Today’s eCommerce firms adopt a multi-channel sales approach – this naturally includes multiple fulfillment centers, on-site teams, and various vehicular fleets. This could get tricky and result in disastrous consequences if not handled properly. Challenges like stock fluctuation, intra-network movement, re-order levels, etc., are naturally amplified due to this multi-channel sales network.

The levels of automation that today’s 3PLs such as WareIQ can bring, thereby reducing human error and ensuring real-time visibility and communication, have become a strong tool for clients.

Forecasting Sales Patterns

3PLs use highly sophisticated data-analytics systems that can record and mine massive amounts of data every second. This comprehensive data analysis generates deep levels of insight that enable management teams to make more informed and effective business decisions.

Detailed reports that provide in-depth information at both the macro and micro levels of client operations and metrics that outline the best practices of sales-based inventory allocation help clients immensely. Channel throughput and efficiency, stock turnover, fast/slow-moving products, etc., are some key data points in determining sales patterns.

Advantages of an Elaborate Fulfillment Network

Today’s eCommerce firms mostly use an omnichannel sales strategy. With its elaborate and extensive network of fulfillment centers, InventoryLogIQ allows clients to leverage the strength and resources of this network in fulfilling their orders. Reduced shipping costs, faster delivery times, and inventory splitting are some of the associated benefits.

Conclusion

Today’s eCommerce companies operate in a fast-paced, highly competitive,and complex eco-system that spans international borders. They deploy an omnichannel sales and distribution network and several fulfillment centers and employ huge teams to manage their inventory. Therefore, firms must use a data-led and technology-enabled inventory allocation system that considers all the numerous variables that affect it to come up with a winning one.

InventoryLogIQ provides commercially certified solutions, professional services, barcode scanning, and technology such as an advanced IMS (inventory management software) to assist businesses in better understanding and controlling their assets, inventory management in the supply chain, and industrial processes. These solutions are quickly implementable and cost-effective, saving you time, money, and effort. We offer extensive knowledge and capabilities in all eCommerce-related requirements, from inventory allocation to order distribution.