What is Distributed Inventory? How It Works & When To Consider Adopting Distributed Inventory Systems Using Multiple Fulfillment Centers?

Every owner of an online store aspires to reach as many clients and geographical areas as feasible. All businesses prioritise expanding their markets and selling to consumers all over the nation. The eCommerce industry is constantly changing.

Online goods and services sales are predicted to exceed $5 trillion globally in 2022 and $6 trillion by 2024. Retailers have flocked to online commerce in record numbers as they continue to follow customer demand. An estimated 12–24 million eCommerce sites exist worldwide, and new online retailers are opening up daily to remain competitive in this industry. As a modern online store owner, one must continuously change tactics and procedures. Distributed inventory is one of the most effective techniques to guarantee maximum reach while remaining competitive.

You might assume multiple warehouses will make order fulfilment by a 3PL more complicated. However, there are numerous benefits to working with a single 3PL with various locations.

Being close to your consumers is one of the most crucial factors to consider when choosing the site of your fulfilment centre. Using a single fulfilment facility can make it nearly hard to effectively reach the vast majority of your clients as they probably don’t all live in the same area.

The fulfilment centre nearest to the consumer will immediately complete the order when a customer places one on your website instead through distributed inventory management.

Let’s examine distributed inventory in more detail and see if it is the ideal inventory and transit management system for your business.

- What Is Distributed Inventory Management?

- How Does Distributed Inventory Work?

- When To Consider Distributed Inventory Management System?

- Top 10 Advantages Of Distributing Inventory Through Multiple Fulfilment Centres in 2023

- Capability for High-Volume Orders

- Distribute The Risk

- Shipping of Oversized and Overweight Products

- Reduced Costs For Shipping and Transportation

- Reverse Logistics Gets Simpler

- Less Delivery Across Borders

- Faster Order Shipping

- Minimize Issues Of Damaged Products

- Improved Inventory Management

- Opportunity To Expand Into Other Markets

- Challenges Faced In Distributed Inventory Management

- Conclusion

- Benefits Of Partnering With WareIQ & Inventory LogIQ For Better Distributed Inventory Systems in 2023

- Distributed Inventory FAQs (Frequently Asked Questions)

What Is Distributed Inventory Management?

Distributed inventory is an order fulfilment methodology that physically stores merchandise in multiple warehouses to be closer to more consumers to reduce shipping distance and time.

In a distributed inventory model, a company spreads its inventory among many carefully chosen warehouses or fulfilment centres, holding a portion in each one (depending on where its customers reside).

Most retailers must work with a third-party logistics provider, or 3PL, to distribute inventory in this way because it is not feasible for one company to handle one (or more) fulfilment centres.

Compared to self-fulfilment, outsourcing saves time and spares you the expense of purchasing the staff, infrastructure, equipment, and supplies required to run a fulfilment centre (such as renting a warehouse or buying property). Although a 3PL’s fulfilment network can enable your company to use the distributed inventory approach, you must first understand how it works to decide if it is appropriate for your company.

With less shipment distance, transit time, and shipping expense, orders can be picked up, packed, and dispatched from the fulfilment centre that is most convenient for their final destination.

How Does Distributed Inventory Work?

A producer or supplier stores its products in a centralised warehouse under a traditional inventory model. After a consumer puts in an order, it is processed for delivery at the hub and then delivered to the customer. When a customer places an order, the warehouse or fulfillment center closest to them has all the items in stock or can fill the demand for the least amount of money and will prepare and dispatch the order.

When there is an unexpected spike in demand for a particular product, these fulfilment centres can also assist others in the network.

Any inventory management system‘s main objective is to ensure the proper amount of inventory is available at the appropriate location and time. The precise amount of inventory required in a specific place is challenging to predict, but machine learning and artificial intelligence are increasing the predictive data process. The widespread use of this technology makes it feasible for inventory distribution to be as precise and customer-focused as possible.

Retailers generally work with a 3PL (third-party logistics provider) to set up a distributed inventory system to accomplish this goal. Together, they determine the retailer’s primary consumer base and what those customers want. Then, depending on the amount and location, the optimum way to distribute inventory can be determined using predictive analytics and purchase history.

When To Consider Distributed Inventory Management System?

An eCommerce seller might benefit significantly by distributing their inventory around several fulfilment centres, a practice called distributed inventory. Working with a 3PL with numerous warehouses allows you to benefit from their experience and knowledge without paying the high up-front costs associated with setting up your infrastructure. If you experience the problems stated below, you should consider hiring a 3PL to obtain the benefits of distributed inventory system.

Your Products Are Heavy In Weight

When a shipment is heavier, it will cost less to ship since it will go farther or via fewer delivery zones. Your products will probably be more accessible to your clients if you have distributed inventories. You will be able to cut back on shipping expenses, which can quickly mount with heavier shipments.

You Deliver A Lot Of Orders

When your business is just off the ground, a single warehouse can be all you need because it will probably be too expensive to run out of many fulfilment centres. However, it will be more cost-effective to distribute your goods around fulfilment centres if your business grows to the point that shipping expenses outweigh the price of extra warehouse space.

You can deliberately pick locations close to your consumers by using numerous warehouses. Because orders will be transported from a nearby location, keeping inventory close to your customers can reduce shipping expenses.

Similarly, rather than keeping inventory for every item you sell, sending only your most well-liked or best-selling products to different warehouses might make sense. By doing this, your less popular products won’t take up warehouse space and hang about collecting dust without selling, saving you from having to pay for storage.

Not All Of Your Consumers Are In The Same Region

Not all of your clients are concentrated in one region of the world.

Where your consumers reside ultimately determines where your fulfilment centre should be situated. This is because orders are delivered more quickly and inexpensively when your packages travel a shorter distance. Therefore, it’s advisable to determine how many customers might profit from an additional warehouse before investing in one.

You Want To Provide Inexpensive 2-day Shipping Consistently

Consumers today are used to expecting two-day delivery when they order online. A large number of fulfilment centres enables quicker delivery. When a customer buys something online, the order is instantly filled from the warehouse that is closest to the customer.

This could allow your business to provide Prime-like service with quicker delivery times to fulfil client expectations.

Top 10 Advantages Of Distributing Inventory Through Multiple Fulfilment Centres in 2023

A distributed inventory model presents several possible commercial benefits. Benefits range from tactical to strategic, and they can enhance a company’s profitability and client pleasure.

Capability for High-Volume Orders

Shipping expenses that exceed warehousing costs are likely to be encountered by retailers looking to expand their companies. The most economical course of action in this situation is to manage activities from many fulfilment centres. Utilizing strategically positioned warehouses is a wise approach to managing inventory because top-selling things may be stored and shipped from different warehouses. At the same time, less-favourite products don’t have to sit around at the company’s expense.

High-volume online retailers can also benefit from better inventory management since 3PLs with numerous warehouses often have their inventory management software for efficiency and transparency.

Distribute The Risk

Natural disasters and other calamities frequently hinder shipping companies from reaching the fulfilment facility or cause delays while in transit. Some of your orders may eventually be affected by a flood, wildfire, hurricane, earthquake, snowstorm, or other natural disasters.

You will have backup inventory in other locations if you divide your inventory among different geographic areas. It can be preferable to be safe than sorry to avoid delays or lost inventory.

Shipping of Oversized and Overweight Products

More warehouse and truckload space is typically required for larger and heavier goods, which adds to the already high cost of these spaces. Retailers can cut storage and delivery expenses by using distributed inventory because their products will pass through fewer shipping zones and are less likely to get trapped in warehouses.

While there isn’t a single best strategy to handle inventory and shipping management, retailers considering order volume and regional market location can make better 3PL provider selections. Distributed inventory can boost eCommerce conversion rates and hasten business growth with a thorough cost-benefit analysis and knowledge of market geography.

Reduced Costs For Shipping and Transportation

Goods are situated closer to clients in a distributed inventory scenario, which lowers transportation costs. This is crucial for overweight and oversized products because they cost more to ship over long distances. Customers may receive some of these savings through cheaper (or even free) Shipping, or the savings may be kept as profits.

Reverse Logistics Gets Simpler

A company has to handle the process of either throwing away the products or adding them back to inventory when a consumer wishes to return something. Those who take advantage of distributed warehouses can reduce the cost and effort associated with these reverse logistics operations. Accepting returns in any place is the ultimate objective.

Less Delivery Across Borders

International markets offer sellers a wealth of opportunities, but Shipping across borders has several drawbacks, including higher costs and customs issues. Working with nearby warehouses or fulfilment facilities is an efficient way to lessen or eliminate such problems.

Faster Order Shipping

Today’s customers anticipate their items to be delivered within a day or two, making quick delivery even more important. You’ll be closer to your clients by distributing your inventory and may complete orders faster. You can opt to store your inventory close to your customers’ locations and deliver the goods the same day or the next day using 3PLs like Inventory LogIQ.

Minimize Issues Of Damaged Products

Products are less likely to be lost or damaged in transit because they do not have to travel as far. Savings are generated for the business that makes those products as a result.

Improved Inventory Management

Organizations that supply their scattered warehouses can better manage the inventory in their structures when combined with knowledge of product demand and client location. As a result, they can operate with less excess inventory than companies that adopt a centralised strategy.

Opportunity To Expand Into Other Markets

A company can enter new markets by being able to send more goods at less money via new locations. Ideally, you would have established a distribution hub before attempting to make sales in the region.

Challenges Faced In Distributed Inventory Management

A distributed inventory strategy has numerous benefits, but there are also some drawbacks that businesses should be aware of. One is cost, particularly for new businesses looking to expand. Different locations frequently result in higher costs, whether from investing in more fulfillment centers or outside logistics companies. For this strategy to succeed financially, businesses must also have excellent inventory forecasting capabilities.

Another element to think about is management. It may be necessary for some firms to collaborate with many 3PLs, which can make partner and customer relationship management more difficult. Working with many vendors could also necessitate the usage of diverse technology by the organisation, such as order management systems. Success depends on effective communication and standard performance measures, which should reduce these problems.

Lastly, it might be challenging for businesses to overcome inventory management obstacles and possess all the inventory intelligence necessary to support a thriving distributed inventory environment. For example, working with 3PLs requires excellent demand planning and supply chain analytic skills to prevent carrying too much or too little stock.

Conclusion

It may be necessary for some firms to collaborate with many 3PLs, making partner and customer relationship management more difficult. Working with many vendors could also necessitate the usage of diverse technology by the organisation, such as order management systems. Success depends on effective communication and standard performance measures, which should reduce these problems.

Lastly, it might be challenging for businesses to overcome inventory management obstacles and possess all the inventory intelligence necessary to support a thriving distributed inventory environment. For example, working with 3PLs requires excellent demand planning and supply chain analytic skills to prevent carrying too much or too little stock.

Related Article: 5 Benefits of Inventory Data Analysis for Your Business in 2023

Benefits Of Partnering With WareIQ & Inventory LogIQ For Better Distributed Inventory Systems in 2023

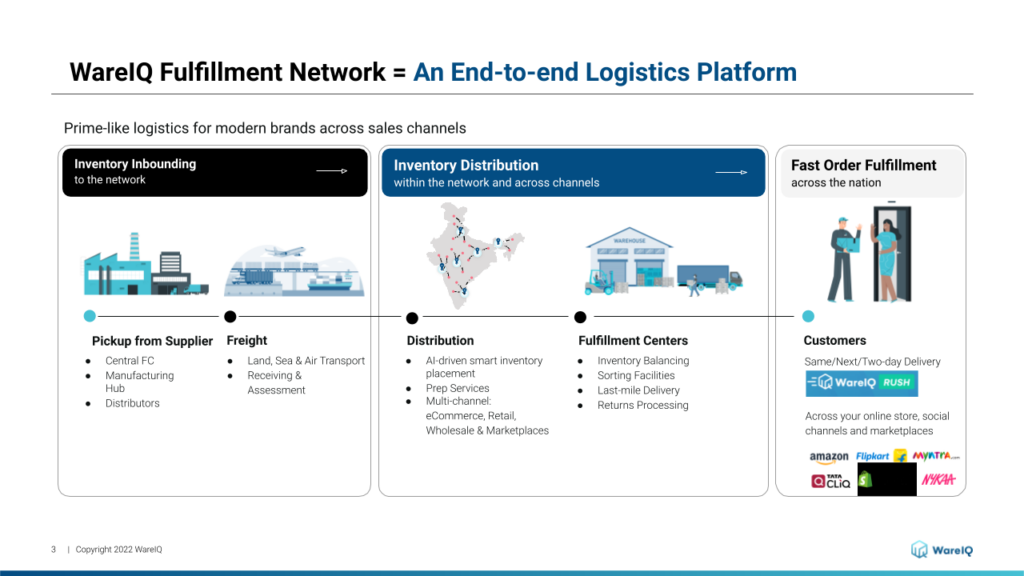

By cooperating with WareIQ, a 3PL partner, eCommerce enterprises who don’t want to manage warehouse management can streamline supply chain management. Self-fulfilment is time-consuming and expensive, requiring a lot of effort, training, certifications, resources, safety precautions, and other costs that make it unattractive.

On the other hand, WareIQ’s supply chain management professionals know how to optimise operations and stay current with emerging supply chain trends and technology.

WareIQ processes orders for numerous eCommerce firms through its extensive network of fulfilment facilities distributed around the nation, allowing businesses to concentrate on marketing, product development, and other activities.

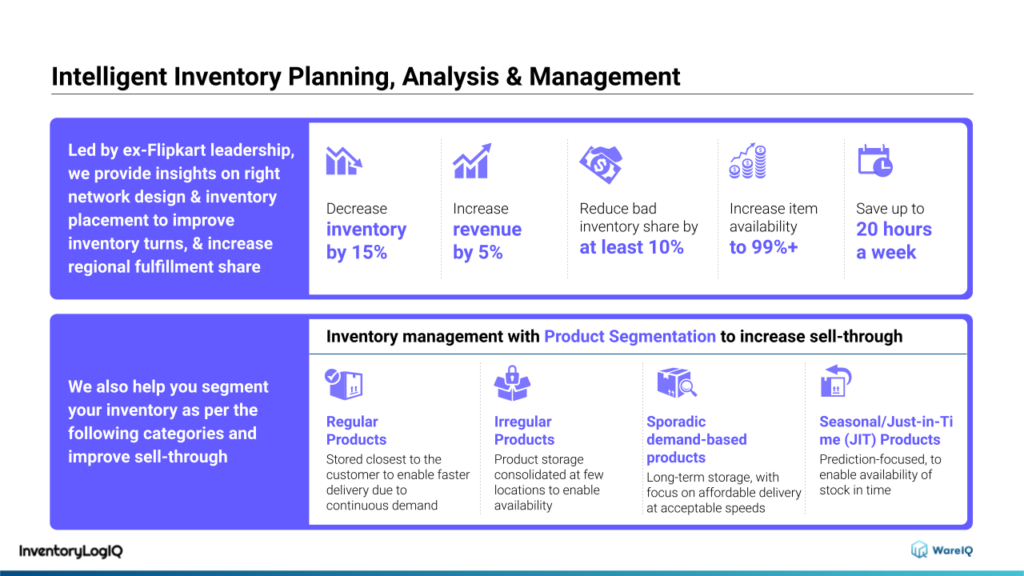

Inventory LogIQ is WareIQ’s AI-based eCommerce inventory optimization tool that enables efficient inventory planning & regional utilization via distributed inventory and smart inventory placement across fulfillment centers and warehouses located across the country.

How Inventory LogIQ enhances your inventory control and distribution system is as follows:

Improved Inventory Control

Inventory LogIQ gives you the data you need to manage inventories without even visiting the FCs where your products are stored. For example, you may set up automated reorder notifications to ensure you never run out of stock and that all product inventory levels are tracked in one place.

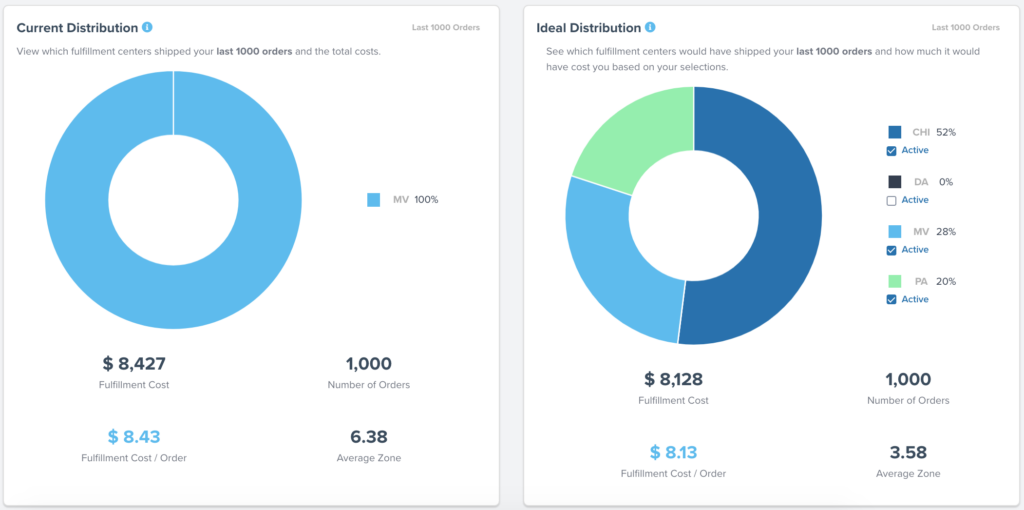

Distributed Inventory

With the help of Inventory LogIQ, you can smartly place inventory across FCs/warehouses closer to your customers and with WareIQ’s shipping partners, you can deliver your items to clients faster and economically. You can reduce your fulfilment expenses by sending orders from facilities close to the customer. As a result, higher customer satisfaction and repeat purchase rates can be anticipated with lower shipping costs and quicker fulfilment.

Order Management

With automated order processing and real-time order visibility via the WareIQ dashboard, you can keep consumers informed while quickly accessing order management analytics and fulfilment performance.