A Definitive Guide to Excess Inventory Including Meaning, Causes, Impacts and Preventive Measures in 2023

There are certain specific circumstances that cause products to be sold slower than businesses anticipate. Some of these include low demand during the off-season, products becoming obsolete, an economic downturn, inaccurate inventory forecasting, and much more. Whatever the causes may be, incorrectly assessing how much inventory you need to order during a particular time period can have severe consequences on the financial and operational capabilities of your company.

For instance, if you order too much of a particular product and you aren’t able to sell it within the intended time frame, it could be at risk of expiring, leading to wastage. Additionally, you will have to continue to pay the fees involved in storing those items. Due to these implications, it should be in your best interest to prevent excess inventory from stacking up. In this blog, we will take a look at the meaning, causes, impacts, and preventive measures of excess stock and how InventoryLogIQ can help.

- What is Excess Inventory?

- What are the Main Reasons for Excess Stock in 2023?

- Negative Implications of Excess Inventory: How Does it Affect Your Bottom Line?

- 3 Simple Ways to Prevent Excess Stock From Piling Up in 2023

- From Overstock to Opportunity: 5 Tips & Tricks to Deal With Excess Inventory

- Conclusion: Streamline Your Inventory Management to Avoid Excess Stock With InventoryLogIQ

- Excess Inventory: FAQs

What is Excess Inventory?

Excess inventory refers to a situation in which a business has more of a particular product or material on hand than it needs or can sell in a reasonable amount of time. This can happen due to a multitude of factors, such as overproduction, changes in market demand, or miscalculations in forecasting. Excess inventory can be a financial burden on a business, as it ties up capital that could be used for other purposes and may not generate any income until it is sold.

Additionally, excess inventory may incur storage costs and may be subject to deterioration or obsolescence. Oftentimes, many companies neglect the accumulation of excess inventory and do not perceive it as a negative, which is a vastly misinformed outlook. Your business should only stock important commodities that are able to be sold and can generate a profit so you can make back the money you have spent producing them.

What are the Main Reasons for Excess Stock in 2023?

Overproduction of Slow-Moving Items

One of the most common causes of excess inventory is overproduction, where a business produces more of a product than is currently demanded by consumers in the market. Primary causes for this include a misjudgment of market demand or an overestimation of sales. It is important to precisely gauge the accurate quantities of SKUs that need to be produced in order to fulfill the demand of customers and adapt production to match the demand generated during different times of the year.

Changes in Market Demand

The market for a particular product or material can change rapidly, and businesses may find themselves with excess inventory if they are unable to adapt to these changes. For instance, if a business is producing a product that becomes obsolete or is replaced by a newer, more popular product, it may have difficulty selling its excess inventory. This is commonplace in industries that constantly introduce new technological features for lower costs, such as electronics, as well as manufacturing and marketing seasonal products, such as Christmas decorations or fireworks.

Miscalculations in Forecasting

Businesses rely on forecasting to predict future demand for their products and materials. However, forecasting is not an exact science and businesses may end up with excess inventory if their forecasts are incorrect. Factors such as unexpected changes in the economy or shifts in consumer preferences can lead to miscalculations in forecasting, which in turn leads to excess stock being present. Investing in advanced inventory management software can help you successfully identify changes in demand and plan in advance to tackle various unforeseen circumstances.

Using Stockpiling of Goods as a Failsafe

Some businesses may choose to stockpile various products as a way to protect against potential shortages or price increases. However, this strategy carries the risk of creating excess inventory if the shortages or price increases do not materialize and trends shift in a different direction. While keeping slightly excess stock of highly demanded products is a common occurrence, it should not be a widely adopted practice due to the vast amount of uncertainties that exist in the market. Therefore, you should manufacture and stock the amount of inventory that is needed to get through a particular season.

Inefficient Inventory Management

Inventory management exists and should be prioritized because it ensures that your business is always primed to fulfill orders whenever it is needed, in the fastest and most efficient way. Poor inventory management practices can also lead to excess inventory. Issues such as inadequate tracking of inventory levels, a lack of attention to inventory turnover, failure to anticipate changes in demand, not placing replenishment orders in time, and much more, are common instances of ineffective inventory management procedures.

Negative Implications of Excess Inventory: How Does it Affect Your Bottom Line?

Increased Storage Costs

Excess inventory takes up space and may require additional storage facilities, which can be costly. Because of limited storage space, excess inventory also reduces your ability to maintain stocks of other items and could cause challenging situations pertaining to order fulfillment, resulting in a poor customer experience. It also lowers profitability by tying up funds in unnecessary areas, such as excess storage, leading to reduced margins on every order.

Wasted Resources and Effort

Excess inventory may lose value over time due to factors such as obsolescence or damage. This can result in a loss of value for the business. If products are kept in storage perpetually, it could also result in expiry, damage or parts needing to be replaced due to non-usage, which negates the ability of those products to be sold and generate a profit for your business. Additionally, demand for products constantly fluctuates so certain items may not be eligible to be sold until the next relevant season, making them redundant.

Requires Additional Resources

Excess inventory can lead to inefficient operational procedures, as it may require additional labour to manage and move the excess inventory. The resources put into constantly shifting and monitoring excess inventory can put a financial strain on the business and also result in more time being spent on managing it than on more important procedures, such as preparing other goods to be picked, packaged and shipped. Because of this, the business wouldn’t be able to operate at full capacity, resulting in reduced sales and unhappy customers.

Reduced Cash Flow

Excess inventory can negatively impact a business’s cash flow, as it requires investment in producing and storing the goods without generating any immediate revenue, which is the primary way businesses are able to make back their money and eventually break even. Additionally, items stored for long periods of time can depreciate and lose most of their value, eventually becoming liabilities that companies need to worry about getting rid of rather than selling them to generate profits.

Diverts Attention Away From Other Processes

Because excess inventory requires dedicated time and effort to manage, resources cannot be utilised in other, more important aspects of the business, such as order fulfillment, replenishing other products, inventory management and more. This creates a volatile environment which could cause other business functions to be neglected, resulting in even more consequences further down the line.

3 Simple Ways to Prevent Excess Stock From Piling Up in 2023

Streamline Your Planning and Forecasting Methods

Planning inventory and Forecasting demand for a specified time period is essential to understanding how much inventory you need to keep stock of for that duration. Failing to do so can result not only in excess inventory but also in stockouts of other products, promoting irrelevant products and much more. It is key to invest in advanced inventory management software that can keep track of your historical order and inventory data so you can identify patterns in previous sales cycles to ensure that the right products are stocked at the right time. This will ensure that you do not have to worry about excess stock.

Utilize Automation Wherever Possible

Using inventory management software and other cutting-edge technology can open the door to the automation of various tasks, which can free up capital and labour, which can then be diverted to other tasks. Procedures such as tracking SKU numbers, identifying accurate products for specific orders, packaging and more, are some of the processes that can be automated. Automations also reduce expenses and your reliance on manual labour, making it faster, cheaper and more efficient.

Implement Marketing Strategies

Sometimes, it is not always possible to entirely prevent excess inventory from occurring. Due to challenging circumstances, such as fluctuating demand, changes in consumer preferences, natural calamities, reduction in the spending ability of customers and more, certain products are at risk of not getting sold. Thus, it is important to account for this by having predetermined marketing strategies that can push these products if such situations occur, helping you to rid your business of excess stock and ensuring that it gets sold before it becomes obsolete.

From Overstock to Opportunity: 5 Tips & Tricks to Deal With Excess Inventory

Liquidate Any Excess Stock

Liquidating excess inventory is one of the most well-known methods of getting rid of it. Inventory liquidators purchase various kinds of stock and resale the items for less money. They specialise in buying unwanted items that businesses are looking to get rid of. They typically purchase goods directly from retailers.

The quickest way by far to sell your excess stock is to liquidate it. However, a major drawback is that it isn’t the most profitable approach. Typically, a liquidator pays as little for the stock as possible. Additionally, the price of delivering the inventory to the buyer must also be taken into account.

Provide Comprehensive Discounts

A good way of getting rid of excess inventory while also generating a decent amount of revenue from it is to offer them at highly discounted rates. Typically, customers are always on the lookout for exciting deals and if they perceive that they are getting their money’s worth out of it, it will definitely be a success.

You can offer various flash sales and clearance drives to generate interest among customers with significantly discounted rates. This will prevent the excess stock from going to waste and also enable consumers to get the product they need at much cheaper rates than they could elsewhere.

Offer Product Bundles

You can provide bundle deals, such as buy one, get one free or buy one and get the second item at 50% off. Additionally, if the products are in sellable condition, there is no requirement to inform that customer that it is excess stock. This will increase brand visibility and create a positive sentiment among customers.

Product bundling is a good way to sell more items at once and generate more revenue from every order that customers place. For instance, if you are selling clothing items, you can give customers the option of getting complimentary accessories like belts, socks, watches and more, to add value to their initial purchase while also ridding your business of multiple items.

Donate Items to Charity

If certain items are taking too long to be sold and continue to gather dust and occupy space in your storage facility, it would make more sense to donate them to a charitable organisation so that they can at least be utilised to their fullest potential. Some products may lie idle to the point they become obsolete and risk expiry or severe wear and tear, meaning that they cannot be sold.

If you deal in essential and useful items, such as food, clothes, electronic devices and more, you can identify an institution, such as a school, old age home or orphanage that you can give away these items to for no cost. It will help generate goodwill among the recipients and garner a positive reputation among customers.

Return Excess Stock to the Supplier

In some instances, you can sell the items back to the manufacturer, who can then sell them externally for whatever price they choose. If you immediately recognize that certain products may not be sold in the volumes you anticipate, or if products become irrelevant due to changing seasonal demand, you can negotiate a deal with your manufacturer so that both parties can benefit and negate the adverse effects of excess stock accumulating.

Keep in mind that sellers can have a variety of different agreements with their manufacturers, with some choosing to pay beforehand, on a per-item basis or in bulk, so identify an offer that would fit with your current arrangement.

Conclusion: Streamline Your Inventory Management to Avoid Excess Stock With InventoryLogIQ

Avoiding the accumulation of excess inventory should be imperative for every online and offline retailer. The unwanted outcomes, such as increased storage costs, product wastage, financial burden and many others, significantly outweigh any intended positive impacts, such as preparing in advance for the scarcity of certain products and resources.

While it does make sense to prepare in advance by forecasting the demand for certain items during particular seasons, it should be done in a systematic fashion and should be backed up with heaps of data. Making uninformed decisions regarding storing additional units of a product or letting excess stock amass is a recipe for disaster. If you need the tools and services to implement streamlined inventory management processes for your business to prevent excess stock, consider partnering with InventoryLogIQ.

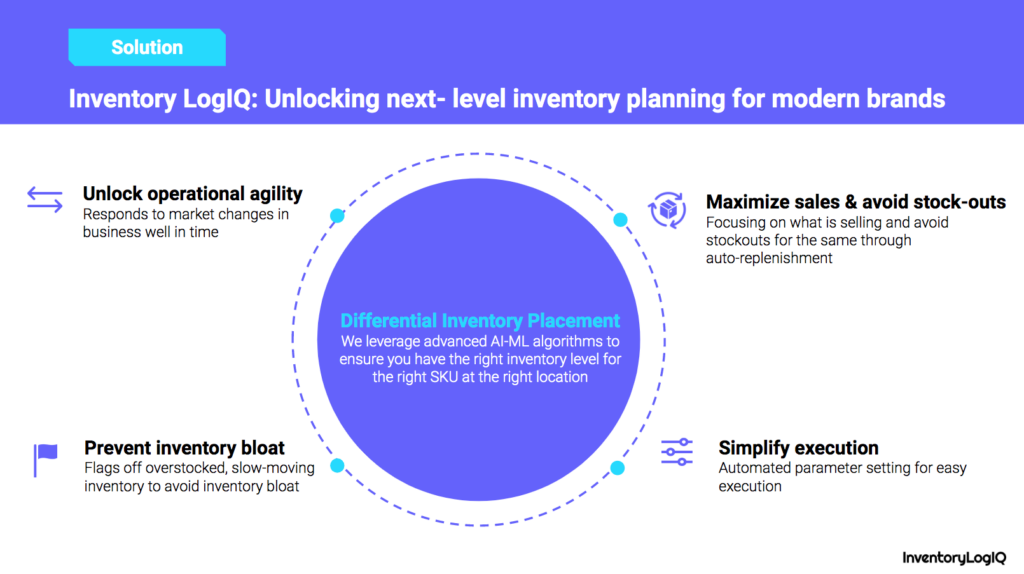

InventoryLogIQ is a dedicated inventory management solution that uses AI and ML to help your business predict future demand and plan ahead. We enable our partners to reduce their operational and storage costs, while also ensuring that they have enough inventory to meet demand and fulfill orders. We offer multiple solutions, some of which are mentioned below:

- Real-time inventory tracking

- Multiple marketplace integrations

- Custom OMS

- Automated replenishment triggers

- Inventory placement recommendations

Suggested Read: What is Dead Stock and How to Prevent it in 2023?