Inventory Flow in Warehouse: Definition, Role, Challenges, Processes and Methods to Enhance Inventory Process Flow in 2023

Inventory is one of the most important assets of any operational retail business. It is generally how companies can account for all the finances spent on research and development, production, marketing and distribution of products and eventually become profitable. Inventory is constantly shifted and transported throughout different aspects of the supply chain and this movement needs to constantly be running optimally to lower your operational and logistics costs, and increase your profit margins. It also enables you to fulfill orders accurately and swiftly to ensure your customers have a positive purchasing experience with your company.

Therefore, certain tactics and strategies need to be implemented to accomplish this and mitigate any risks associated with the flow of inventory throughout the supply chain. In this blog, we will help you understand the definition of inventory flow, the role it plays in inventory management, the challenges associated with it, the processes involved and 5 methods to streamline your inventory flow in warehouse operations.

- What is Inventory Flow?

- The Role of Inventory Flow in Managing Inventory

- What are the Challenges Associated With Inventory Flow?

- The Various Phases Involved in Inventory Flow in Warehouse Operations

- 8 Methods to Enhance Your Inventory Process Flow in 2023

- Conclusion: Take Advantage of InventoryLogIQ to Optimize Your Inventory Flow

- Inventory Flow: FAQs

What is Inventory Flow?

Inventory flow refers to the physical movement of goods, products and raw materials as they enter and exit a company’s inventory and are transported through various operations in its supply chain. It encompasses all the processes involved in acquiring, storing and selling products to customers, from the time of purchase to the final delivery. Inventory flow is a critical component of a company’s supply chain management, as it affects the availability of goods, the accuracy of inventory records and the ability to meet customer demand.

In a typical inventory process flow, goods are received at the company’s warehouse or storage facility, where they are inspected, counted and stored. The company then updates its inventory records to reflect the addition of new products, which can be tracked using a variety of tools, such as barcode scanning or automated inventory management software. Effective management of inventory flow can help your company improve their bottom line and ensure a seamless customer experience.

The Role of Inventory Flow in Managing Inventory

Product Sourcing

The entire supply chain process commences once raw materials are transported to suppliers and they can convert them into finished products that are then transported to their client’s storage facilities. Inventory flow also helps companies maintain accurate stock levels by tracking the physical movement of goods in and out of the warehouse. This helps ensure that the company always has the appropriate amount of inventory to meet customer demand.

Inventory Storage

After receiving a consignment of products from their suppliers, companies need to find the most effective and appropriate ways of storing them so that they can be easily identified and accessed whenever an order comes in. This can involve storing heavier items on lower shelves, grouping similar items together or consolidating products of similar value and price in the same storage space. Whatever storage strategy you choose, it should result in better inventory management by being able to locate an item, package it and dispatch it as soon as an order is confirmed.

Order Fulfillment

Inventory flow is essential for ensuring that orders are fulfilled quickly and accurately. Order fulfillment involves transporting inventory from the warehouse to distribution centers and ultimately to the end customer’s location. By monitoring the movement of goods through the supply chain, companies can identify bottlenecks and make changes to improve fulfillment processes and hasten delivery speeds, resulting in increased customer satisfaction and a more positive opinion about your business among existing and prospective customers alike.

What are the Challenges Associated With Inventory Flow?

Inaccurate Inventory Data

One of the biggest challenges in inventory flow is ensuring that inventory records are accurate and up-to-date. This can be difficult due to manual errors, data entry errors or the use of outdated tracking methods. Inaccurate data can result in overstocked or understocked inventory, missed sales opportunities and decreased customer satisfaction. Therefore, it is essential to employ the use of an advanced OMS that can automatically keep a tab of all the important information pertaining to your inventory and provide real-time updates whenever there is a change in your inventory levels. This will help mitigate the negative effects of inaccurate data.

Logistics Issues

The physical movement of goods can be disrupted by transportation problems, such as traffic, weather conditions or unexpected events, which can cause delays in the delivery of goods and impact inventory flow. Additionally, if different parts of your company’s supply chain are not integrated and communicating effectively, it can result in disruptions to inventory flow and negatively impact the overall efficiency and structure of your supply chain. To prevent these unwanted issues and negate their adverse effects on your business, you will need to conduct supply chain forecasting and make the necessary preparations to curtail unforeseen challenges that can impact your supply chain.

Technology Limitations

Reliance on outdated or inadequate technology can also present challenges in inventory flow, as it can limit your ability to track goods and maintain inventory records in real-time, making it more difficult to manage the flow of inventory effectively. This can also extend to other areas of your supply chain, such as the use of outdated delivery vehicles, inefficient receiving and storage techniques, and a lack of communication facilities between various departments. As stated above, using advanced inventory management software, identifying areas of limited productivity and shovelling more funding towards those processes can help streamline your inventory flow and run your supply chain smoothly.

The Various Phases Involved in Inventory Flow in Warehouse Operations

Receiving Finished Goods

This is the first step in the inventory flow process, where finished goods are received from suppliers and checked for accuracy and quality. The received goods are counted and cross-checked with the purchase order to ensure that the correct items have been received in the specified quantities.

Storing the Received Items

The received goods are then stored in designated locations within the warehouse, known as putaway. This process involves finding an appropriate storage location for the goods and ensuring that the inventory records are updated accordingly. Finding the right storage space can depend on various characteristics of the product, such as weight, dimensions, value and more.

Picking the Relevant Products

The next step is locating an ordered product, where they are selected from the storage locations and prepared for shipment. This process involves the use of a picking list, which lists the items that need to be picked and the quantity required to fulfill the order. The items are then taken to the packing area for preparation.

Packaging Ordered SKUs

The picked items are then packaged and readied for dispatch, ensuring that the appropriate security measures are taken to protect the goods during transit. The packaging process also involves labelling the packages with the necessary information, such as the destination and contents.

Shipping Dispatchable Items

The packaged goods are shipped to the customer’s mentioned location in this phase. This process involves preparing shipping documents, such as invoices and bills of lading, and arranging for the shipment to be picked up by the carrier, from where it is taken to the customer’s city and completed by the last-mile delivery personnel.

8 Methods to Enhance Your Inventory Process Flow in 2023

Use a Warehouse Management System

A WMS is a software system that helps to manage the flow of goods within a warehouse. It helps to automate processes such as receiving, putaway, picking, packaging and shipping, and provides real-time visibility into inventory levels and locations by sending you alerts whenever changes occur. Additionally, all this information can be accessed through a single dashboard and it can also synchronise data across multiple storage locations and online selling platforms, enabling you to monitor your inventory and order data from anywhere with a stable internet connection and login access. Because of all the functionality it provides, it can ease up the way your inventory flows through your warehouse and supply chain.

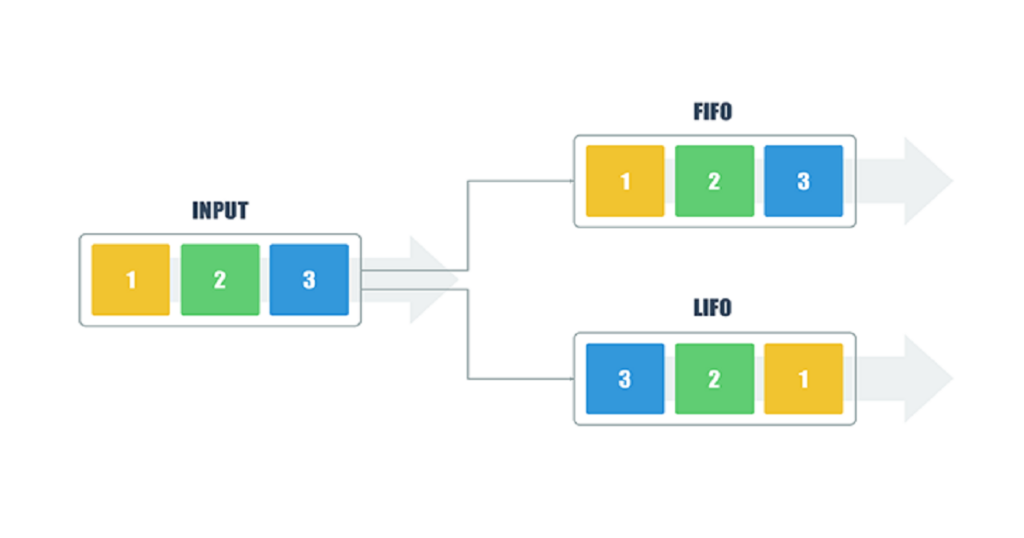

Implement a FIFO/LIFO Accounting System

FIFO is a method of inventory management where the oldest items in inventory are sold first. It helps to reduce the risk of obsolescence and spoilage, and ensures that the most recent inventory is sold first. Conversely, LIFO is a method of inventory management that focuses on selling the items that have arrived last, so they can be prioritised. Which one you choose will depend on the nature of your business and its products but implementing either of them will allow you to have a set structure in place when selling your inventory, helping your inventory flow to happen more efficiently.

Utilise Batch Picking

Batch picking is a method of selecting the items needed for multiple orders at the same time, rather than picking each item individually. This method helps to reduce the time spent on identifying products and increases the efficiency of the picking process. Warehouses are generally filled to the brim with a vast array of products in different shapes and sizes, so batch picking can optimise inventory flow by tackling a large number of items at once, which helps in reducing the overall time and effort spent on readying the products for specific orders.

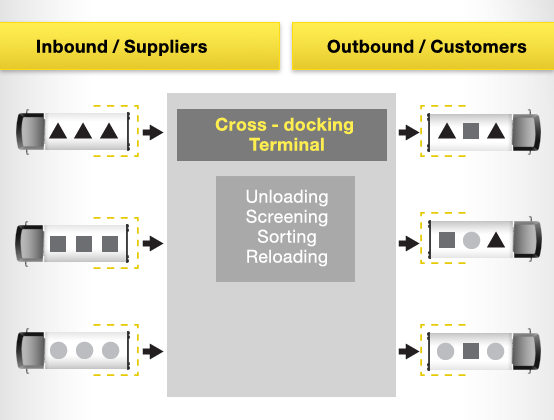

Employ the Use of Cross-Docking

Cross-docking is a method of inventory management where incoming goods are directly shipped out without being stored in a warehouse. This method helps to reduce the time spent on putaway and picking, and increases the speed of the inventory flow process. Because items do not need to be stored before they are dispatched, it also helps save on storage and operational costs, and ensures that items reach their relevant destinations ahead of schedule. This can help free up additional storage space needed for bulkier or more important products.

Implement Cycle Counting

Cycle counting is a method of continuously counting a portion of your inventory on a regular basis to ensure that the inventory records are accurate. This method helps to identify and resolve any discrepancies in the inventory records and ensures that the inventory information is up-to-date. Using cycle counting will ensure that issues can be resolved quickly and will not lead to bottlenecks and confusion further down the supply chain, allowing inventory flow to be consistent and unhindered.

Utilise Barcoding and RFID Technology

Barcoding and RFID technology help to track the movement of goods within a warehouse and provide real-time visibility into inventory levels and locations. This helps to reduce manual errors and increase the efficiency of the inventory flow process. Additionally, it is quite simple to achieve. All products within your storage facility will simply need to be fitted with a scannable tag after which they will be entered into the system and can be tracked by a barcode scanner using its assigned code which will make tracking inventory a more seamless task.

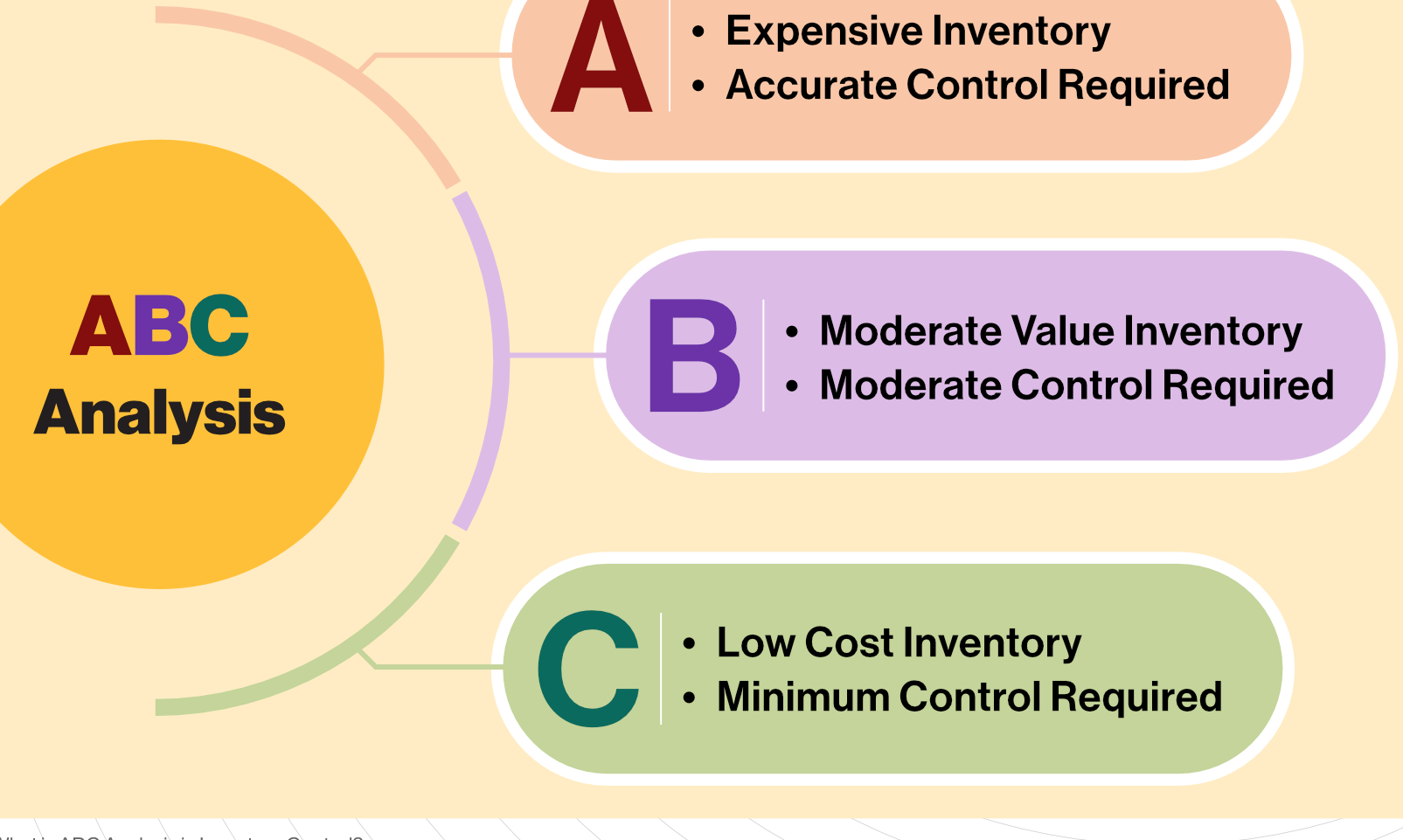

Conduct ABC Analysis

By employing the ABC analysis method, your business can examine stock utilisation and manage inventory flow more effectively. This strategy divides inventory into three categories – Group A stands for products with a low supply but significant profit margins, Group B includes items that are currently available and priced in a reasonable range and Group C comprises SKUs with a low price range and that are always readily available. By maintaining appropriate safety stock levels that offer flexibility in the event of unforeseen demand variations, your company will be able to control inventory utilisation. Hence, you can maintain productivity, sales and revenue by ordering the right amounts of each group of commodities.

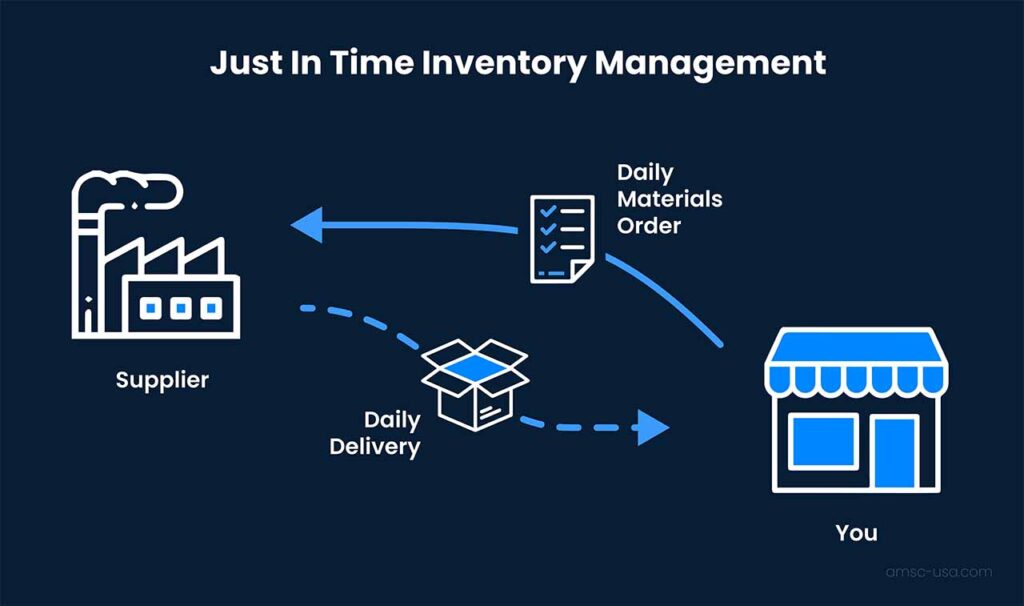

Use Just-in-Time Inventory Management

Quick inventory turnover is a symptom of using the Just-in-Time (JIT) inventory system, which combines logistical understandings and analysis to guarantee that all orders are shipped and delivered in accordance with their demand. Businesses generally buy goods on a per-order basis which helps in cutting lead times, rather than storing products for later use. This strategy necessitates in-depth familiarity with market patterns and variables like weather, geography and political events that might impact the amount of time it takes to deliver goods. If logistical risks are not taken into account, orders could be delayed and customers may become dissatisfied. However, companies that successfully apply the JIT strategy can shorten lead times while also having low amounts of inventory on hand.

Conclusion: Take Advantage of InventoryLogIQ to Optimize Your Inventory Flow

The seamless movement of inventory throughout the supply chain is essential to your business’s success and smooth functioning. Because inventory is one of the most crucial aspects of your business, it is essential to make sure that every facet of inventory management is taken care of, including inventory flow. The flow of inventory can encompass many different processes, from sending raw materials to your supplier to transporting finished goods to your customers’ doorsteps.

Therefore, your entire business will benefit as long as those operations are running efficiently. The benefits of having a competent inventory process flow are immense from reduced inventory costs to enhanced customer satisfaction. If you need assistance with improving your inventory flow and other aspects of your inventory management process, InventoryLogIQ is the solution you need.

InventoryLogIQ is a premier inventory management solution that provides your business with all the tools and facilities it needs to safeguard your inventory and ensure it is managed effectively. Some of the services we provide are listed below:

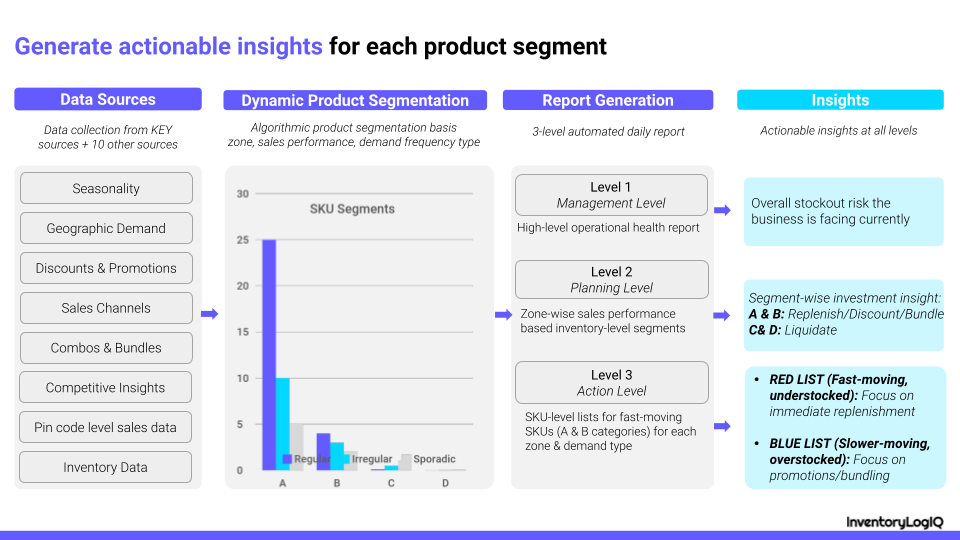

Tracking Inventory Levels

We offer detailed analytics for inventory level monitoring to allow for frequent reviews of inventory positioning and to react to changes in the business while maintaining ideal inventory levels.

Streamlining Storage Space

We provide blue lists that identify unsold or excess inventory, which are presented in a simplified manner in order to save storage space.

Bundling Products

We help businesses increase sales by locating the ideal products for promotional bundles and combinations by providing insights into every SKU.

Segmenting Inventory

We enable you to keep an eye on daily demand fluctuation and separate rapidly selling products from sluggish movers that require more concentration and attention.

Replenishing Inventory Levels

We preside over the success of your items and red-list goods that are getting close to running out of stock, which can be found using reports from retail replenishment planning analytics and can help in preemptive stock replenishment.