What is Lead Time in Inventory Management? The Significance of Having a Short Inventory Lead Time in 2023

In every online and offline retail business, the central focus is placed on researching, manufacturing and delivering products to customers. However, the time taken to complete each of those tasks and all the more granular ones between them is equally important. For instance, if you started creating promotional hype around your brand and its products, but a manufacturing delay causes the items to take longer than expected to be fulfillment-ready, it could disrupt your entire supply chain and worsen your brand image in the eyes of customers.

Therefore, a large amount of attention should go towards maintaining and eventually reducing the time it takes from the start to the commencement of important processes. When you take the time to streamline each procedure by cutting out any excess steps, your entire supply chain will benefit and so will your customers. In this blog, we will delve deeper into the meaning of lead time in inventory management, how it is calculated, the factors that affect it, and different types of inventory lead time, 5 ways to reduce it and how InventoryLogIQ can help.

- What is Lead Time in Inventory Management?

- How is Inventory Lead Time Calculated?

- Factors That Affect Lead Time in Inventory Management in 2023

- The Benefits of Having a Short Inventory Lead Time

- 5 Easy Ways to Reduce Inventory Lead Time for Your Business in 2023

- Conclusion: Partner With InventoryLogIQ to Lower Your Inventory Lead Time

- Lead Time in Inventory Management: FAQs

What is Lead Time in Inventory Management?

Lead time in inventory management generally refers to the length of time between the start of the process of placing an order and the completion of receiving the items in your storage facility. Lead times can differ across industries and the nature of processes being measured, so there cannot be a consistently accepted lead time across the board.

Knowing the lead time of various operations gives businesses the advantage of being able to prepare in advance and get everything in order before the scheduled time. This ensures that every process is running at its most efficient capacity in terms of productivity, duration and cost-effectiveness. Lead times are often calculated for different processes at various stages of production or fufillment, pertaining to manufacturing, project and supply chain management and can refer to tasks before, during or after production and processing takes place.

How is Inventory Lead Time Calculated?

Summary of Steps Involved in Inventory Lead Time Calculation

- Find the cause of the supply delay

- Identify the impediments to reordering

- Add up the supply and reordering delays

Example of Inventory Lead Time Calculation

The reordering delay must be taken into account as a first step in the lead time calculation. Include the time needed for the manufacturer to confirm and process the purchase order when estimating the total time needed to receive an order from your supplier. Therefore, if your supplier accepts reorders only once every week and you place an order four days prior to the day the order would be approved by the supplier, your inventory needs to last an additional four days.

The reordering delay, in this case, would be an additional 4 days. The lead time is the result of adding the supply delay – the amount of time it takes for a shipment to arrive at your inventory – and the reordering delay. According to this scenario, the lead time formula is mentioned below:

Inventory Lead Time = Total Days in the Supply Delay + Total Days in the Reordering Delay

Your overall inventory levels are directly impacted by lead time. If you have a long lead time, you will have to consider keeping more products on hand in your inventory. Deliveries will also become increasingly more unpredictable with longer lead times, forcing you to place orders largely reliant on demand estimates. Following the calculation of your lead time, if you are not satisfied with the results, you will need to take corrective measures to reduce it.

Factors That Affect Lead Time in Inventory Management in 2023

Supplier Lead Time

This is the duration of time it takes for a supplier to prepare and ship an order after it is received. Since the lead time of the supplier isn’t really in your hands, it pays to have constant communication so that both parties can be aware of the preferences and desires of the other. It can also be impacted by the pace with which suppliers accept an order and start the groundwork for producing the relevant products. It is important that suppliers have a low lead time so that it can have a positive snowball effect further down the supply chain.

Production Duration

If the product is manufactured rather than purchased directly from a supplier, the production time will also impact lead time. Even if you do obtain your goods from a supplier, the time they take to manufacture and eventually ship your goods is also a factor because you cannot start to fulfill orders until you receive your order. It is important to have an efficient and timely production process so that products can be received on time and last-minute additions and edits can be made if needed.

Transportation Time

The time it takes for the product to be shipped from the supplier or manufacturing facility to your business’s storage facility also plays a big part in your overall inventory lead time. Additionally, this is the stage where your products would be the most susceptible to external influences, such as traffic, roadwork, natural calamities and more. Thus, it is important to be ahead of the 8ball and ensure your products are shipped and stored in your warehouse at least 1 to 2 days before the deadline to avoid getting affected by unwanted circumstances.

Order Quantity

Lead time can be impacted by the quantity of the product being ordered and how much of the product is already in stock. If more units of a product are required for replenishment, it will obviously take more time to manufacture, load and transport, contributing to an increased inventory lead time. Conversely, if orders are small in size and the production timeline is short, it will contribute to a lower lead time. Hence, it is important to plan ahead when it comes to placing purchase orders.

Unexpected Increases in Demand

Inventory lead time can increase when the supplier or manufacturer does not have the product in stock or when there is unexpectedly high demand for a certain item. If your manufacturer does not have the capability of producing those orders within the predetermined time span, it could increase lead times and cause delays further down the supply chain. It is important to forecast demand and account for sporadic increases in demand for certain items to lower your lead time in inventory management.

The Benefits of Having a Short Inventory Lead Time

Improved Inventory Management

By having a clear understanding of lead time in inventory management, businesses can better plan and optimize their inventory levels for different situations. This can help to reduce the risk of stockouts, as well as the costs associated with carrying excess inventory. Since the time taken for every process is accounted for, every task involved with inventory management can be more efficiently executed and will result in always having the right amount of inventory at the right time, reducing the duration of tasks like picking, packing, and dispatching of orders in the process.

Increased Efficiency Across the Board

With a clear understanding of inventory lead time, your business would be able to better plan and schedule production, which can help to increase efficiency and reduce costs. In addition, it will help you also account for unforeseen circumstances since you have an estimate of the time it takes to complete specific tasks. This will have a positive impact further down the supply chain and result in boosted efficiency in every facet of your business and its interaction with customers.

Enhanced Customer Service

A well-managed inventory lead time can also help businesses to provide better customer service. By having a clear understanding of when goods will be available, businesses can better plan for and meet customer demand. This will result in shorter fulfillment times, fewer delays and fewer mishaps and errors. Due to this, customer satisfaction will skyrocket and they will vouch for the experience they had with your company through reviews, online forums and spreading the word among their friends and family. This will increase your chances of generating repeated sales and acquiring potential new customers.

Reduced Costs

A properly administered inventory lead time can also help businesses reduce costs in several important ways. For instance, by reducing the risk of stockouts, businesses can avoid the costs associated with lost sales and expediting fees. They can also save money by removing unnecessary and additional processes in an effort to cut down on the inventory lead time of each task. It will also enable you to keep the appropriate quantity of inventory in stock, cutting down your purchasing expenses by a significant margin.

Increased Flexibility

Having a short inventory lead time for each task can also give businesses greater flexibility to respond to changes in demand or unexpected events. Because you have the knowledge about how long it takes to complete certain tasks, you can conduct forecasts and plan ahead more effectively, as opposed to playing the waiting game and being caught off-guard when an unwanted situation arises. Being aware of your inventory lead time will make it simpler to play around with your inventory management procedures so you can find the sweet spot for what works for your business.

5 Easy Ways to Reduce Inventory Lead Time for Your Business in 2023

Reduce Order Volumes by Increasing the Frequency

Consider ordering lower quantities that will require shorter durations to create and ship as opposed to placing huge orders that will fill your storage for the next couple of months. This way, your inventory gets refilled more regularly and reliably, and you can account for any disparities between items received and the order that was placed.

Additionally, increasing your order frequency will allow you to be more prepared and secure your inventory for unanticipated circumstances since smaller orders can be more easily edited to accommodate last-minute changes to certain items.

Validate Your Suppliers Based on Their Performance

Include a lead time clause in the contracts you have drafted with your suppliers. If they deliver items far sooner than you or they anticipated, you can give them a bonus and highlight their productivity. Conversely, if they are late in delivering an order or there are inconsistencies in the products received, they can receive a suitable penalty.

This aids in encouraging your suppliers to follow the established inventory lead times and will keep them on the right path. It will also increase transparency by making sure that each party knows their role and responsibilities in detail.

Implement Automation for Important Procedures

By utilizing automations for your inventory management operations, you can shorten the time it takes to pick, pack, ship and fulfill orders. By using cutting-edge inventory management software, you can manage and create purchase orders more quickly, stay in touch with your suppliers at all times and keep track of stock levels without having to worry about manual data entry or human mistakes.

They also provide many others perks, such as providing low stock alerts, automating replenishment triggers and sending notifications regarding order and inventory data in real-time, making it convenient for you to keep a tab on all your inventory management procedures from a single digital location.

Source Your Products and Services Locally

It should not be a surprise that inventory lead time drastically increases when your products are shipped from distant vendors. Finding suppliers in different, less expensive countries or regions may seem enticing because of the possible reduction in production expenses but in the long run, waiting for stock to arrive may end up costing your company in a variety of ways, leading to reduced profit margins and negative sentiments among customers.

Finding local suppliers might considerably shorten your lead time and will enable you to have multiple backup options in close proximity in case there is a delay with one of them.

Get Rid of Unproductive Procedures and Other Bottlenecks

Eliminating various stages or processes that are not actively required or can be merged with something else that results in a reduction in effort, time, and financial resources while improving on the end result is one of the simplest techniques to reduce inventory lead time.

This can entail forgoing numerous quality control checks, reducing the frequency of evaluating the production process’ effectiveness, and even eliminating procedures pertaining to the acquiring of inventory. Nothing saves more time than completely ousting or optimising a specific task so it is important to identify which ones are not absolutely essential to the ultimate goal that you are trying to achieve.

Conclusion: Partner With InventoryLogIQ to Lower Your Inventory Lead Time

Overall, inventory lead time is an important aspect of supply chain management and inventory control that can have a big influence on a company’s ability to meet customer demand, manage costs and maintain good customer service. By monitoring and managing lead time, businesses can work to minimize risks and ensure smooth and efficient operations. Inventory lead time can be a critical factor in determining a business’s customer service success.

Long lead times can lead to stockouts and delays in fulfilling customer orders, which can negatively impact customer satisfaction and, ultimately, the business’s bottom line. It is also important for businesses to measure and monitor lead time, using metrics such as average lead time and on-time delivery rate. These metrics can help identify problem areas and allow your business to take steps to improve its lead time and customer service. If you need help with improving your inventory lead time, InventoryLogIQ can be the solution you need.

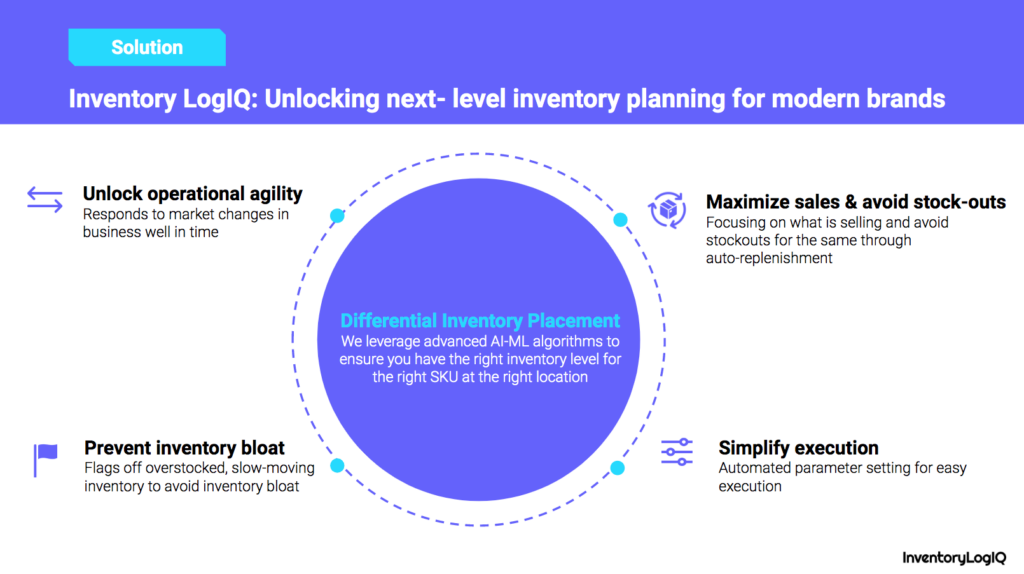

With the use of AI and ML, InventoryLogIQ, a specialised inventory management solution, can assist your company in anticipating demand and preparing for it. We make it possible for our partners to cut back on operational and storage expenses while still maintaining enough inventory levels to meet demand and complete orders. We provide a variety of options, some of which are mentioned below:

- Tracking Inventory in real-time

- Integrations with multiple marketplaces

- In-house OMS

- Triggers for automatic replenishment

- Recommendations on where to place inventory

Suggested Read: Why Are the KPIs Important to Track & Monitor in 2023?