Retail Replenishment: Importance, Strategies & Best Practices of Stock Replenishment for Retail Businesses in 2023

It has been observed that 88% of businesses have experienced late shipping. In comparison, 34% of businesses ship orders late because the products are out of stock at the time of purchase, an essential element in the eCommerce supply chain that affects consumer loyalty and the entire brand experience. Ineffective stock replenishment significantly influences a retailer’s gross margin return on investment (GMROI), resulting in lost sales due to out-of-stock or overstocking expenditures and markdowns.

Although meeting customer demand has always been difficult, effective retail replenishment could reduce problems caused by inadequate planning and allocation. It is even more crucial for merchants to have a solid strategy for stock replenishment in retail businesses to live up to the modern customer expectations of inventory availability and quick order fulfilment. Let’s identify the main aspects of stock replenishment before moving on to the methods and most acceptable practices of retail replenishment.

- What is Retail Replenishment for eCommerce Retailers?

- Why is Stock Replenishment in Retail Important?

- 5 Steps for Retail Replenishment Planning

- Step 1: Have a Thorough Understanding of the Entire Business

- Step 2: Compile a List of Distribution Factors Particular To a Given Product

- Step 3: Recognize the Particular Distribution Procedure for Each Product

- Step 4: Whenever Feasible, Use Advanced Analytics and AI

- Step 5: Prepare Yourself to Manage Risks

- Strategies to Optimize the Retail Replenishment Process

- Best Practises for Stock Replenishment in Retail Businesses in 2023

- Conclusion: Gain Access to Smooth Retail Replenishment with InventoryLogIQ

- Retail Replenishment: FAQs

What is Retail Replenishment for eCommerce Retailers?

Retail replenishment, also known as inventory or stock replenishment, focuses on ensuring the business places new orders from suppliers in time to satisfy consumer demand. Retail replenishment may also refer to shifting inventory from reserve storage to primary locations so that it can be utilized to complete orders for retailers, distributors, and manufacturers with numerous inventory storage facilities. Businesses may benefit from effective retail replenishment, including preventing stockouts and overstocking, lowering shipping costs, and increasing consumer happiness.

Unfortunately, the stock replenishment process in retail enterprises may be exceedingly complicated despite being crucially critical for firms holding hundreds or thousands of inventory items, partly because things may need refilling at various periods and rates. Companies that sell through many channels and need to manage inventories for each may find the issue particularly acute. In addition, retail replenishment is complicated and dynamic, making paper-based manual procedures quickly obsolete. Due to this, manufacturers, distributors, and retailers are increasingly utilizing technology to improve their organization’s overall view of their inventory situation and to automate the replenishment process.

[contactus_uth]

Why is Stock Replenishment in Retail Important?

Stock or retail replenishment is a crucial procedure that directly affects an online brand’s capacity to satisfy consumer demand, complete orders, and generate revenue. The following three points explain why retail stock replenishment is crucial for shops:

Prevents Stockouts

A stockout, or having things that are out of stock at the moment of purchase, is possible if a retailer does not replace inventories properly. Backorders are another possibility, which indicates that an order has a set shipping date for the item. Unfortunately, backorders and stockouts may both make your consumers extremely angry. Having safety stock, a set quantity of backup or emergency inventory on hand at all times is the best approach to prevent typical stockout concerns. This is also a smart move in case of sudden supply chain problems.

Eliminates Overstocking

A clever retail replenishment procedure may also aid in preventing overstocking of items with expiry dates, such as food and drink or cosmetics, which may become unsellable if left on the shelf for an extended period. Overstocking can harm your bottom line, much like having insufficient inventory does. Dead stock can result from replenishing inventory too soon or without considering seasonality or variations in consumer demand, which raises carrying costs by allowing unsold merchandise to remain on the shelves for an extended period.

The economic order quantity (EOQ) formula is an easy-to-use method for calculating the appropriate stock level to maintain and meet order demand, assisting in avoiding overstocking and high transportation costs for retail warehouses. You can more precisely predict how much inventory, including safety stock, you should have on hand by calculating EOQ, which will also help you keep the cost of your eCommerce warehouse to a minimum.

Reduces Shipping Costs

Consider the scenario where a customer places many orders with you simultaneously. If one item is out of stock at the closest warehouse location for the customer but is available at another location, you would need to send another shipment (sending different items from one order in separate packages, frequently from a different location or at a different time) to fulfil the customer’s entire order. Multiple shipments of the same order’s contents result in higher shipping costs, significant packaging waste, and perhaps confused consumers. By projecting demand, you may choose how much stock at the SKU level to keep in various warehouse sites based on previous data.

5 Steps for Retail Replenishment Planning

Step 1: Have a Thorough Understanding of the Entire Business

Retail companies sometimes divide their operations into several categories, with top business leaders only accountable for their particular category (such as inventory allocation, selection, replenishment, and vendor relations) and nothing else. As a result, communication quickly breaks down since one category plan might not consider all other category plans.

Bring your category heads together to map out all the critical corporate elements that affect your retail replenishment process to solve this. You’ll then need to collaborate to create a unified process that considers the entire product life cycle, from the time an order is placed with a vendor to the time it is made available for sale to the customer, to resolve this issue correctly.

Step 2: Compile a List of Distribution Factors Particular To a Given Product

The demand must be taken into consideration while making your replenishment supply plans. Demand is merely one of the factors that must be taken into account, as was previously noted. You also need to be fully aware of the precise distribution path used by your goods. Will the seller restock the shop with your merchandise inventory directly? Or will it move from the vendor to the warehouse, distribution centre, and loading docks?

You also need to be aware of the demand in each place. While some of these facilities solely service certain retailers, others may directly complete client orders. Be aware that the market fluctuates depending on the type of business and the store’s location and that each store may have different plan-o-gram minimums and capacity restrictions.

Step 3: Recognize the Particular Distribution Procedure for Each Product

Resupply is sometimes referred to as S&OP or sales and operational planning. This is because retail stock replenishment depends on many variables during a product’s life cycle. As a result, to handle replenishment in a coordinated and comprehensive manner, you must have a thorough knowledge of every aspect of the distribution (as well as all the channels the product may be sold through). Some distribution-related parameters include:

- Production Time

- Time For Shipment and Packaging

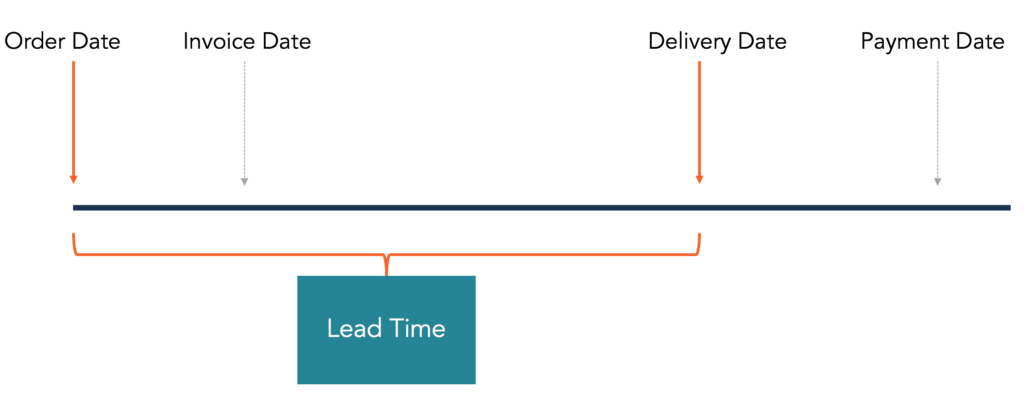

- Lead Time

- Time Spent Processing At The Warehouse

- Fulfillment Of Customer Orders

- Order’s Distributions Promotions

These elements must be taken into account as part of replenishment, along with other activities that occur in a retail company, as well as emotional capabilities and operations.

Step 4: Whenever Feasible, Use Advanced Analytics and AI

The majority of merchants try to handle retail replenishment manually. To achieve this, they must examine items at the category level and ignore several crucial elements. As a result, this technique is unreliable, unworkable, and results in overstocks, lost sales, and high distribution costs. Leading merchants have realized they need to automate as much as they can.

By taking a detailed look at a retailer’s merchandise, advanced AI technologies and analytics models created for retail replenishment can produce a unified predictive analysis of every component described above. To maximize GMROI and ensure that consumers can obtain the items they came to your business, replenishment is optimized at an SKU and store level.

Step 5: Prepare Yourself to Manage Risks

When your system has been optimized for the vast majority of predicted product behaviour, it’s time to concentrate on the remaining 20%. Some dangers may be anticipated since they are well known, such as factories stopping production on specific holidays. Such occurrences are readily accounted for, and retail replenishment may be planned around these anticipated risks. However, some dangers, like unforeseen weather events, cannot be anticipated. A contingency plan is a crucial component of a solid retail replenishment strategy. Before creating a contingency plan, ask yourself the following questions:

- Can you bring inventory from a different facility or vendor?

- Can you swiftly purchase safety stock and distribute it?

- Is it possible to relocate your inventory to a new location?

Strategies to Optimize the Retail Replenishment Process

Models and techniques for inventory replenishment assist companies in establishing inventory slotting best practices, managing replenishment frequency, monitoring inventory flow, calculating the number of items to order, and determining the ideal inventory level to be kept in warehouses for maximum supply chain effectiveness. In addition, these mathematical formulas aid warehouse managers in deciding how much inventory to order at preset times. Let’s examine a few of the most well-known replenishment models:

Minimal or Maximum Inventory Replenishment or Reorder Point Strategy

The min/max replenishment model, called the “routine” technique, initiates refilling operations when a particular product hits a specified minimum threshold. The most significant applications for this are SKUs with consistent throughput and seasonally predictable demand. Replenishment orders are placed in this arrangement when inventory levels reach a certain level (the reorder point). Although this replenishment model’s ordering costs are minimal compared to other expenditures, carrying costs are frequently high, and more space may be required for upstream storage and downstream pickup areas.

Demand Retail Replenishment

Demand replenishment is a simple tactic that benefits many organizations. The only time suppliers restock is when customers ask for it. The store doesn’t place another order for a product that isn’t selling. This approach makes out-of-stock situations frequent but solely due to client demand. The demand inventory replenishment approach is appropriate for warehouses with constrained picking areas and floor space. It works well when it would be inefficient to devote a lot of space to a single object. The replenishment amount in a demand replenishment process should be enough to complete an upcoming order or collection of orders without leaving behind extra stock.

The inventory of a business should be checked often. The best system is an automated one. These systems provide real-time inventory tracking, keeping suppliers and merchants in the loop. Additionally, businesses must be prepared to satisfy shifting client needs. Keeping track of popular goods and maintaining back supply is essential. For the procedure to be effective for the business, meticulous planning is required. To implement this strategy, both a supply and a demand plan need to be established.

Top-Off Restocking of Inventory

The top-off replenishment approach often operates on a defined timetable or batch releases. It has similar min/max criteria to the min/max replenishment model (by area, line or product). In picking regions or forward pick sites, the inventory for a particular product is “topped-off” to acceptable levels based on the anticipated demand or a change in the number of available staff members.

When huge waves or volumes of picking tasks are anticipated, this model performs effectively. It works best when there is a labour shortage or when picking operations are less busy. Interleaving possibilities in active regions are encouraged by a system that initiates top-off replenishment when differences in picking activity or volume are anticipated.

Periodic Replenishment Strategy

The quantity of inventory required for specific periods (based on demand estimate) is transferred to picking locations in warehouses using periodic replenishment models. Typically, review points are utilized after these periods to determine how much inventory is still on hand. Resupply orders are issued if stock levels drop below the required minimum. If not, they are not reviewed until the following review point.

As a result, this model has longer lead times and ought to be employed when there is a sizable product storage area (because inventory is moved in large volumes to picking locations). Conversely, carrying costs are often insignificant compared to ordering costs, and ordering prices are typically unrelated to carrying costs.

Suggested Read: What is a Periodic Inventory System?

Best Practises for Stock Replenishment in Retail Businesses in 2023

Every shop faces different demands, problems, and obstacles when stocking up on supplies. Standardizing something with so much inherent variability may be challenging. Your replenishment procedure should adhere to the following five recommended practices to control the volatility of inventory levels:

Establish Precise Lead Times

Lead time describes how fast the supplier can complete the order. This procedure aids companies in determining the ideal frequency of replenishment to avoid shortages. Lead time is of utmost importance, particularly for businesses that use last-minute replenishment tactics like Top-Off or Reorder Point Strategy.

Internal Business Retail Replenishment

Internal replenishment of inventory can be transferred between stores( you can read here how to carry out inventory transfer? ), which can alter how inventory levels are balanced. Store A may have strong demand, but store B may not; by restocking store A with items from store B, you may match sales demand while clearing off shelves and spending less time and money. A single inventory platform that provides visibility into inventory across all sales channels and locations is necessary for effective inter-store balancing.

ABC Evaluation

Identify and rank the SKUs in your inventory mix according to how much they contribute to sales. The shop may maximize the width and depth of its selection mix after doing an ABC analysis. This analysis may be very simple for a smaller shop, but as the firm expands, it gets progressively more challenging. Omni-channel retailers use analytics-driven retail inventory management solutions to process the millions of data points and SKUs needed for an ABC analysis.

Keep Track and Evaluate Vendor Performance

Retailers should monitor vendor performance for the best vendor management, similar to how they would analyze product performance. There should be precise, measurable KPIs that can be measured and tracked, such as the total amount of damaged or missing goods or orders dispatched, lead times and delivery delays, stock shortages, and so on. Setting a deadline for reviewing vendor performance is advised. After that, actual deliveries are contrasted with the predetermined KPIs.

Inventory Management Software

For a smaller store, manually maintaining their inventory on spreadsheets is acceptable. However, to control replenishment, they can employ a systematic strategy. However, inventory management’s complexity rapidly increases with every new channel, location, and SKU. A “divide and conquer” omnichannel merchants sometimes use strategy to control the expansion of their business. Visibility is limited by segregated channel operations, which causes merchants to be less adaptable and less able to make quick changes. Others have opted for an integrated strategy for managing inventories. For example, retailers can easily spot replenishment opportunities and demands using the warehouse management system(WMS). They can also benefit from inventory balancing and replenishing between stores.

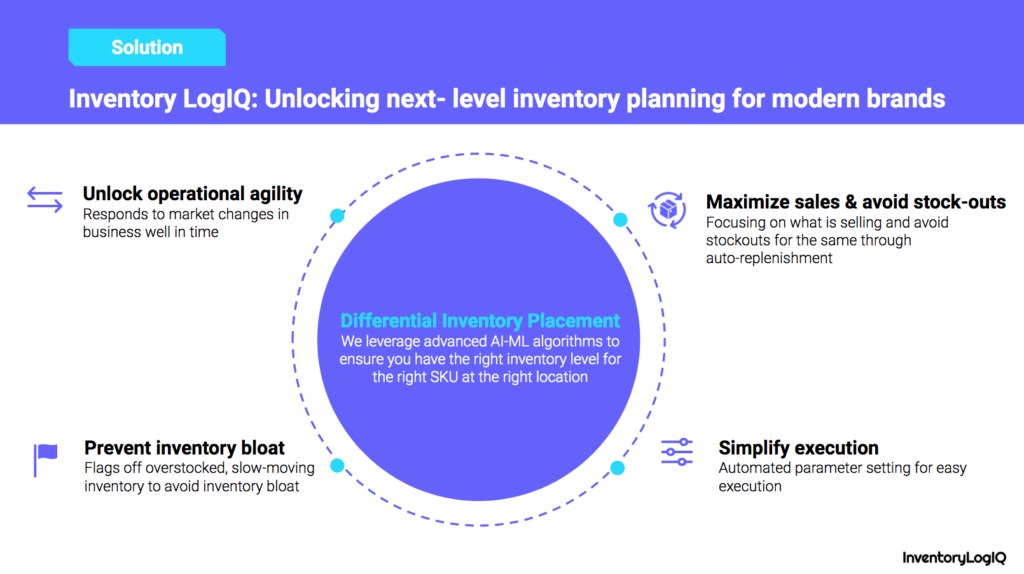

Conclusion: Gain Access to Smooth Retail Replenishment with InventoryLogIQ

Retail replenishment is an essential part of the retail industry and helps retailers to keep their inventory levels optimal, reducing the risk of stockouts and ensuring high levels of customer satisfaction. Whether through manual processes or software solutions, effective replenishment is critical to the success of any retail operation. Any inventory management system must include effective retail replenishment. It enables suppliers, distributors, and retailers to minimize excess inventory while ensuring they always have the appropriate quantity of stock to fulfil consumer demand. Automated inventory management solutions let businesses more easily handle the challenges of retail replenishment, which boosts profitability while cutting costs.

InventoryLogIQ is an inventory management solution for modern brands in India. The technology used by InventoryLogIQ comprises a sophisticated data and analytics reporting tool and integrated inventory management software. You can monitor inventory levels in real-time, establish automatic reorder points and get critical inventory analytics from a single dashboard, such as inventory forecasting tools. InventoryLogIQ puts everything you need at your fingertips to manage inventory and precisely complete orders, allowing you to streamline your supply chain and save time.