What is Inventory Aging? How to Calculate Average Inventory Age and Prepare an Inventory Aging Report in 2023?

Running a retail business can never be more fun when your products are flying off the shelves and you have enough stock on hand to precisely satisfy every request. What happens, though, when your SKUs begin to gather dust? Stagnant or excessive inventory can result in significant problems, such as rising storage costs and reduced profit margins. However, considering inventory aging is a practical way to avoid the pitfalls of unsold inventory and maintain your cash flow because it provides outstanding visibility into your stock and enables you to make inventory adjustments as necessary.

As a result, aging inventory is a popular measure among product-based companies. The potential for expansion in online retail is limitless. However, it’s not always as simple as vendors assume to get merchandise off digital shelves and into the hands of your buyers. Because, in reality, eCommerce is a fast-moving industry. Additionally, because of inventory distortion, businesses currently lose a staggering $1.1 trillion annually as their inventory ages minute by minute.

The good news is that you can easily avoid many of your most considerable stock-related problems if you understand what inventory aging is and how to calculate it. This blog will introduce you to the fundamentals of inventory aging and essential indicators for keeping ideal stock levels and provide helpful advice for maximizing sales and inventory expenditures. Let’s begin!

- What is Inventory Aging?

- The Negative Consequences of Inventory Aging

- What are the Benefits of Monitoring Inventory Aging in 2023?

- What is an Inventory Aging Report?

- How to Calculate Average Inventory Age?

- How To Detect Aging Inventory?

- 7 Best Tips to Avoid Inventory Aging in 2023

- Conclusion: Inventory LogIQ Can Help You Prevent Aged Inventory Scenarios in 2023 and Beyond

- Inventory Aging: FAQs

What is Inventory Aging?

The phrase ” inventory aging ” refers to stocks that hardly move, products that haven’t sold rapidly, or at total retail value. Retailers monitor their aging inventory because, after a certain amount of time, if an item hasn’t sold, they may need to price it down to get rid of it and make room for new inventory. Generally, a brand’s potential for profitability increases with how quickly it can exhaust its inventory.

The optimal inventory age, according to theory, might be as little as a week, a month, or even 90 days after the supplier’s delivery date. But on the other hand, most businesses see products that remain unsold for more than 180 days or six months as dead stock.

The Negative Consequences of Inventory Aging

Accepting the reality that certain things aren’t selling pays off, as harsh as it may sound. However, if you don’t, you’ll still have to deal with inventory aging, which has a variety of adverse effects, including:

Inventory Might Expire

Your inventory probably has a time limit on how long it may be used. You should be much more cautious if you provide meals or items with a food component. You won’t be able to make any money from your inventory if it runs empty.

Warehouses Will Run Out of Space

Your warehouse will have less room to hold new products with a more aged inventory. Therefore, you will need to purchase extra storage or reallocate your current inventory to store more products. Your overall production costs will thus rise due to the rising facility charges.

Outdated Inventory Will Need to Be Marked Down

It will be challenging to sell your merchandise the longer it sits in the warehouse. As a result, you could choose to mark it down and sell it for less than its total retail value. If you are prosperous enough, you might be able to break even by selling it for what you paid for it. However, in most situations, outdated inventory might cause a loss for the providers.

Increased Expenses For Quality Maintenance

These expenses include warranty claims, customer service, and repairs. Extra expenses are unavoidable to guarantee a superior client experience without the knowledge provided by inventory aging data.

High Storage Costs

Your storage and utility costs will increase as your supplies get older. Examining inventory aging might aid in locating slow-moving products if more storage space is needed. In addition, you now have the chance to make room for more quickly moving goods that may have been stored there.

Poor Inventory Management

Managing your inventory well enables you to keep an eye on the distribution, management, and storage phases of the life cycle of your supplies. Stocks become more susceptible to depreciation if no one monitors inventory aging throughout that cycle.

What are the Benefits of Monitoring Inventory Aging in 2023?

When management teams periodically review inventory and keep an eye on how long things are left in the warehouse, they can act promptly to protect their brand’s bottom line. For instance, the business might plan fresh marketing initiatives to boost sales if a product is slow-moving. Knowing how old your inventory is can help you make wise purchasing decisions and safeguard your company’s financial health. Calculating average inventory age and preparing inventory aging reports have further advantages, which include:

Reduces Unnecessary Warehouse Expenses

Carrying costs for excess goods left in warehouse facilities may apply, mainly if the business leases storage space from outside sources. Additionally, the items occupy precious warehouse space that might be utilized for products with a higher profit margin. Sales and potential clients may be lost as a result of this. Business teams may quickly remove out-of-date products from their warehouse or storerooms using dated inventory reports to detect them.

Ensures High-Quality Inventory Goods

Offering high-end, trendy products is the primary objective of many businesses. For instance, supermarket companies must ensure their perishable products are sold before they go wrong, and clothing stores want to sell in-vogue and in-season items. Managers may make sure that their items are up to par by understanding the popularity and calibre of their offerings using aging reports.

Avoids Overstocking

Businesses should manage their purchase and replenishment strategies to avoid overstocking by identifying which inventory items are ineffective. As a result, they can avoid paying for unnecessary warehousing expenses and guarantee that resources are dedicated to profitable merchandise.

Provides Information About Consumer Demand

Understanding the age of your product might help you better understand client demand. Additionally, you may utilize these data to create more precise inventory planning based on what customers truly want (or don’t want). Take the case of an SKU that sells quickly. That indicates a high level of demand, and to prevent a stockout, you might wish to acquire a little bit more safety stock. However, demand is minimal if you don’t sell a lot of an SKU. As a result, you don’t want to purchase a tonne more of that item to have it go out of stock.

Identifies Unsellable and Slow-Moving Products

When you routinely run an aging inventory report, you can determine which goods have a slow turnover rate and aren’t selling. This allows you to head off the issue before those goods become dead stock by offering a discount on the SKU, including it in product bundles, or altogether rebranding the out-of-date products.

Enables Well-Informed Decisions

Knowing which of your products are difficult to sell or slow-moving gives you the power to decide how to raise demand for those products (and subsequently increase your revenue). This might entail reaching out to a new market with those sluggish sellers, combining them with more well-liked SKUs, or lowering their retail price.

What is an Inventory Aging Report?

A financial report calculates the typical number of days merchandise remains unsold in your warehouse and is termed an inventory aging report (also known as an aged stock report). This analysis may help brands discover slower-moving SKUs so they can apply tactics to boost their inventory turnover ratio and stop certain products from going out of stock. Aged stock reports typically consist of the following simple information:

- Numerous SKUs

- Units available for each SKU

- The average inventory age of products in the warehouse

Using spreadsheets and regular inventory checks, you may produce these reports manually. However, this method is laborious, time-consuming, and prone to mistakes made by humans. Therefore, most retail firms employ inventory management software to automate these processes and create these data in real-time.

How to Calculate Average Inventory Age?

Calculating the average inventory age is a crucial component of inventory management to identify inventory inefficiencies and lost earnings. You must know your average inventory cost, cost of goods sold (COGS), and inventory turnover ratio (ITR) to calculate the inventory age for your product listings.

Know The Average Cost of Your Inventory

The volume (or worth) of a company’s inventory during a specific period is estimated by average inventory. An average cost estimate evens out these unexpected jumps either way. It provides a reliable indicator of inventory valuation, smooth if inventory levels might vary dramatically based on seasonality when shipments are received and other factors. Use the following calculation to get your average inventory cost:

Average Inventory Cost = Annual Cost of Goods Sold ÷ Total Ending Inventory

For eCommerce businesses of all sizes, having a firm handle on these figures may be powerful since they show if the volume of goods you’re holding is truly hurting your bottom line.

Be Aware of Your Cost of Goods Sold

The cost of creating the commodities a company or brand sells is the cost of goods sold. The COGS amount includes costs directly associated with manufacturing (such as labour and raw materials), but it excludes several secondary expenses (like overhead and marketing). The following is the COGS formula:

Cost of Goods Sold = (Beginning Inventory + Purchases During Period) – Ending inventory.

In this case, the quantity left over from the prior period is considered the starting inventory (month, quarter, etc.). Purchases throughout the Period, as the name implies, indicate the cost of the items you bought within the specified accounting period. Everything that didn’t sell within that same period makes up ending inventory.

Consider Your Inventory Turnover Ratio

The inventory turnover ratio measures how frequently a business sold and replaced its inventory over a certain period (like over a year, for example). Making better-educated judgments about pricing, marketing, production, and acquiring new stock may benefit eCommerce enterprises. The inventory turnover formula is:

Inventory Turnover Ratio = Cost of Goods Sold ÷ Average Inventory During Period

A slower ratio usually denotes high sales or insufficient inventory levels, whereas a slower ratio may indicate weak sales or significant excess inventory. In either case, ITR is a crucial tool for identifying potential regions for inventory growth.

Multiply by the Number of days

The average number of days it takes to sell out specific SKUs is reflected in the age of your inventory. As a result, analysts typically use this measure to evaluate how well a company’s sales are doing. As a result, the average age of the stock is occasionally referred to by the term “day sales in inventory” (DSI). Use the following equation to determine the average inventory age for your products:

Average Inventory Age = (Average Inventory Cost ÷ Cost of Goods Sold) x 365

In general, it is advised that merchants verify this number using other inventory measurements (such as gross profit margin).

Example For Calculating Average Inventory Age

For instance, a company’s average inventory age would be 146 days if its COGS for that inventory were $500,000 and its average inventory cost was $200,000.

($200,000 average inventory cost / $500,000 COGS) x 365 days is 146 days for the average inventory age.

The longer it takes for a product to sell through and the greater your holding costs will be, the older your typical inventory is on average. As a result, the demand will be more robust, and you will need to be more attentive about placing a reorder in time to prevent a stockout the lower this number is.

How To Detect Aging Inventory?

Keeping outdated inventory is a significant expenditure for your company, and neglecting it may worsen matters. Here are four methods for maximizing inventory control by identifying your aging goods:

Manually Tracking Inventory

You must write down every stock movement when using a manual inventory system. The delivery of the supplier to the point of sale, together with any subsequent transfers, is where the process begins. The average age of the inventory may then be calculated based on your observations of their life cycle. The least expensive option on this list is manual inventory aging tracking. However, this approach is ineffective, mainly if you deal with hundreds of daily transactions. Additionally, it takes up too much staff time that might be used for other, more crucial responsibilities.

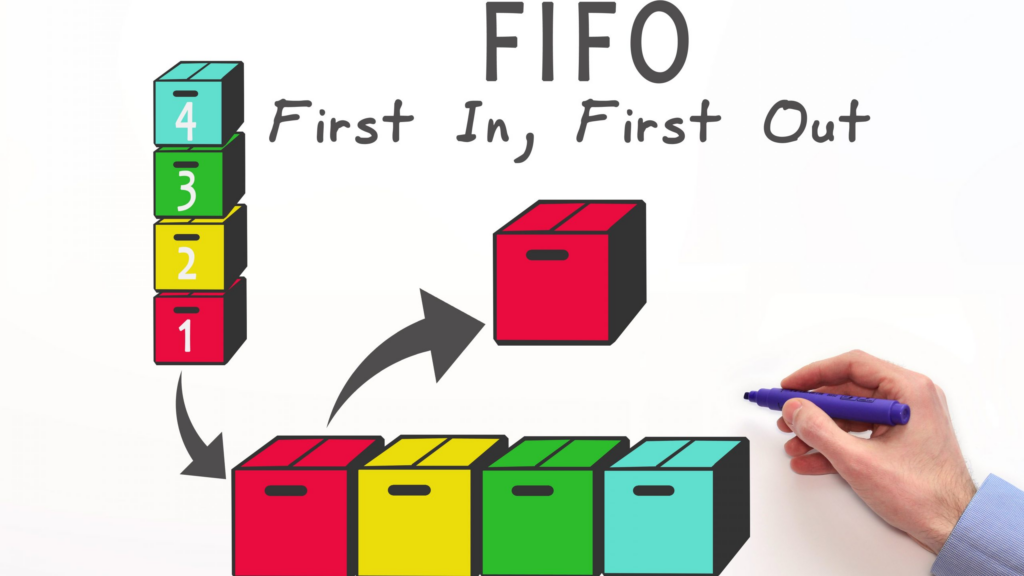

First-In, First-Out (FIFO) Approach

The acronym FIFO, which means first in, first out, says it all: the first things placed in the storerooms are the ones that are made available for purchase first. Therefore, it would help if you recorded each item’s unique purchase dates using this storage and recording technique. In this manner, you may identify and eliminate obsolete inventory that doesn’t move inside the standard time frame. For supermarkets that offer perishable goods with expiration dates, FIFO is a typical strategy. But due to its complexity, maintaining it without AI assistance is challenging.

Spreadsheets

Spreadsheets, especially MS Excel, are well-known for helping small businesses keep track of the age of their inventory. The average age of inventory is determined using a procedure that includes manual data entry and computerized computing. But if your personnel has the methodology and navigational skills necessary to guarantee the report’s accuracy, this won’t work. This method has certain limitations, one of which is that it cannot give the inventory team real-world data. In addition, this task is arduous and error-prone without automation. Another employee could place a fresh order, resulting in surplus stock if, for example, one person gets the cargo but does not update the sheet.

Software for Automated Inventory Management

All the tasks mentioned earlier are carried out by inventory management software with the added benefit of automation. With it, you can keep track of everything and instantly extract inventory aging data. Moreover, since the system adjusts balances continuously, it is hard to ignore the objects that move slowly. When utilising the software, you may quickly obtain a list of quick and slow movers. Additionally, it immediately removes your aging inventory from your next replenishment, enhancing the long-term scalability of your company.

7 Best Tips to Avoid Inventory Aging in 2023

Knowing the average age of your inventory may help business owners see underperforming SKUs, estimate client demand more accurately, and spend less money on incorrect goods. But only if they use that knowledge to decrease their obsolete inventory. Here’s how to go about it:

Enhance Collaboration Between Procurement and Warehouse

You can keep an eye on whatever SKUs you have too much of or aren’t selling rapidly with inventory management KPIs like inventory aging. And you don’t keep adding to your holding expenses by buying more of those things. However, it would be best to let your buying and warehouse management personnel know about this choice. In this method, your buying department won’t unintentionally place another order for that item number. Additionally, your warehouse management staff is aware that no additional inventory is anticipated, so they may utilize that space for other items (this small gesture can seriously improve your fulfilment relationships).

Conduct Routine Inventory Audits

Inventory audits regularly ensure that your stock records reflect what is in your warehouse. This increases inventory accuracy and clarifies which goods aren’t moving (leading to better inventory control). You will then know which SKUs sell well and which do not. Following that, you may choose how to decrease (or remove) the low-demand inventory by holding a marketing event to boost demand.

Examine The Causes Of The Low Sales Volumes

SKUs that aren’t selling typically have a good cause behind them. Seasonality, Website positioning, or shifting consumer patterns are common culprits. You may improve the efficiency of your inventory management by knowing the cause. For instance, you may alter your purchase choices or marketing initiatives to eliminate the extra old inventory.

Improve Demand Forecasting Accuracy

Inventory aging is significantly impacted by inaccurate inventory forecasting, particularly when it is predicted that a slow-moving SKU would be more in demand than it is. However, you may pick better products when you develop operational strategies utilizing synchronized, real-time data. Keep an eye on your inventory all the time. As a result, you must change your inventory strategy as soon as the demand for your products falls. You won’t need to make further orders for things that won’t sell if you do it this way.

Consider Customer Ratings

Customer ratings and reviews are an important part of the decision-making process for many consumers. They can provide valuable insights into the quality of a product or service, as well as the level of customer satisfaction. It is a crucial piece of data that provides the business with the information they need to make informed decisions regarding their inventory levels. Low-rated goods frequently have higher returns and a lower DRR (day run rate), which causes the old stock to accumulate.

Monitor Your Sell-Through Rate in Terms of Discounting

Reduce discount rates to examine how it affects your disabled revenue rate (DRR). If DRR decreases as a result, the approach cannot be deemed a success and is not long-term sustainable. Conversely, raise the discount to see how it affects your DRR. If DRR doesn’t rise with higher discounts, liquidate and halt new orders. Alternatively, the sell-through threshold can be estimated as 1% every day as a rule of thumb. However it may differ from category to category. Unit economics should be used to determine the ultimate discount threshold.

Check Your Rev/List Count Shares

An online platform’s list count is comparable to a physical store’s foot traffic. Everyone’s annual plan PowerPoint usually includes a lever for increasing revenue while maintaining the same list size for better conversion. To accomplish this, the positioning of items, offers and brand callouts is done in a way that generates more money from the same number of list subscribers. Styles that generate less money while maintaining the same visibility are prioritised less and eventually become dated. After an initial push through PLAs, the listing position of the item when that product category is searched can be used as a proxy for visibility in the case of D2C businesses selling on marketplaces.

Conclusion: Inventory LogIQ Can Help You Prevent Aged Inventory Scenarios in 2023 and Beyond

Inventory aging is an issue that is sometimes unavoidable, particularly for large businesses that have a lot of warehouses and a lot of inventory. However, it could be challenging to accurately track all the inventory on hand and forecast the costs associated with acquiring additional inventory; therefore, whether someone is experiencing trouble managing already-aged inventory or is attempting to make predictions about the possible amounts of stock that may age, automation tools and inventory management software come in handy.

Want to get even more advantageous than getting rid of old stock? Avoid overstocking SKUs with weak sales before it ever starts. This could present specific difficulties for retail companies. But fortunately, Inventory LogIQ can assist!

Inventory LogIQ‘s inventory optimization solutions enable you to work more intelligently and generate more sales. Inventory LogIQ is a source of accurate inventory information that enables you to see which goods are selling (and which are ageing) and take appropriate action. Here’s how we can help:

- We provide accurate demand projections based on current inventory levels and historical trends to help you avoid being trapped with SKUs that don’t sell quickly.

- We offer sustainable operational strategies to achieve your boldest sales targets (with the power to effortlessly pivot when demand shifts).

- We provide optimized POs with automated replenishment warnings to help you avoid running low on inventory.

Suggested Read: Inventory Position: Definition, Importance, and 3 Ways To Position Your Inventory In 2023