What is Inventory Planning? Importance, Challenges, and 5 Best Methods of Inventory Planning for eCommerce Businesses in 2023

The eCommerce industry’s ethos is placing products in storage in optimal quantities so they can eventually be sold when an order is placed online. There is a lot of strategic supply chain planning behind every successful eCommerce firm, especially regarding inventory planning and management. Inventory is the most valuable asset for eCommerce sellers. With good inventory planning, you can fulfill orders by efficiently forecasting demand and enhancing the customer buying experience.

When inventory planning is done correctly, it helps online sellers save money and time and streamlines their entire eCommerce supply chain. Customer expectations will be constantly met, and enterprises will remain prosperous. If you struggle to plan your inventory, you need to identify the tactics and tools that will help you improve your inventory planning operations.

What is Inventory Planning?

Inventory is the greatest asset of an eCommerce business, whether it is a retail, wholesale, or manufacturing unit. If we set aside store management and human resource expenses, sellers invest considerable capital in inventory planning.

Inventory planning is when an organization determines the optimal quantity of listed products concerning time and other factors. Inventory planning is an essential component in the supply chain management of eCommerce that involves demand and inventory forecasting to determine optimal inventory levels across each SKU that needs to be maintained in any period to avoid loss of revenue due to stockouts or excess inventory pileup situations.

It is an integral part of a company’s supply chain management strategy alongside order management, accounting, warehouse operations, and customer management.

Inventory planning is unavoidable since it allows businesses to run continuously. Low inventory levels can result in unfulfilled orders, which ruins a brand’s reputation. On the other hand, having too much stock is detrimental to a healthy cash flow and stifles corporate growth because money held up in excess inventory cannot be spent in other parts of the company. It entails anticipating demand and determining how much inventory to order and when to order it. This allows businesses to meet demand while also lowering costs.

In other words, by keeping the correct amount of inventory in the right place at the right time, organizations can lower their overall storage costs, improve inventory planning and control and ensure that there is always enough stock to fulfill demand (whilst avoiding obsolete surplus stock).

Why is Inventory Planning Important?

Increases Sales

Sellers can stock up on products that appeal to their target demographic, increasing sales and revenue. During seasons of high demand, they will have enough inventory available to fulfill as many orders as possible.

Improves Cash Flow

Practicing inventory planning ahead of time might help eCommerce sellers to avoid problems like having too much capital locked up in their inventory. They will be able to keep inventory moving while also freeing up cash to reinvest in the company.

Utilizes Storage

Holding inventory costs a lot of money; if it is a perishable product and needs special conditions and temperature, the cost instantly multiplies. So here, tiny storage space can cost more than the business receives in profits. Inventory planning takes care of inventory space and utilizes it to the best of its ability.

Forecasts Demand

Better demand forecasting helps to make better and more informed decisions about inventory planning and revenue generated in the future. Placing an order during high demand can cost more than procuring it during price slumps or discount periods.

It not only assists a seller in meeting customer demand but also in making better financial decisions that affect profit margins, cash flow, inventory allocation, warehousing, staffing, and overall logistics spending.

Improves Customer Satisfaction

Customer satisfaction is the best selling point. Buyers are always choosy, but they will be satisfied if the seller has the right products at the right time. People often pay more to get a better experience and quality products. They are more inclined to return to the same seller if they can count on getting the things they need and want. Satisfying these desires will help them get a positive outlook on your brand, which will reflect in their feedback

Minimizes Overstocks and Stock-Outs

Inventory planning aids retailers in avoiding overstocking or understocking. It aids in the optimization of inventory storage and precise control over each item. Overstocking can hold up business capital for an extended period. In contrast, understocking can disrupt the supply chain process, resulting in more expensive procurement and an inability to fulfill orders.

What are the Challenges of Inventory Planning?

Managing Huge Amounts of Data

When a seller runs flash sales, their sales velocity increases, and they store much data obtained from buyers. This data is instrumental while running campaigns, checking for follow-ups, and sending personalized offers and benefits according to customers’ gender, last purchase, amount they spent previously, etc.

Managing this useful and colossal data is a challenging task. It needs a good inventory management application that stores data and takes care of qualified leads by marking them as prospects.

In the absence of a cohesive view of the past, current inventory levels, and any other essential sales data, sellers may flounder in the dark regarding inventory-led decisions. This is why implementing a real-time inventory tracking system is non-negotiable.

Finding Reliable Data

Real-time data is required for a smooth and efficient supply chain process. However, information is frequently not maintained in a meticulous manner, especially when it is done manually.

It is distributed throughout several systems even when it is kept track of. This makes it challenging for merchants to consolidate all the data to get a complete picture of their inventory.

A real-time inventory tracking system guarantees that sellers have reliable data as they expand into new sales channels and further develop their distribution network. Various inventory apps make it simple for online retailers to keep track of their inventory.

InventoryLogIQ not only stores the seller’s inventory at their preferred domestic fulfillment sites, but the seller also gets access to inventory data via a single dashboard.

That way, sellers can save the time and effort associated with updating many spreadsheets while reducing human error.

Suggested Read: When To Consider Adopting Distributed Inventory Systems Using Multiple Fulfillment Centers?

Developing Inventory Management Software

Customers have high expectations for the speed with which their orders are processed and shipped. However, getting bogged down in planning and managing inventory can harm supply chain efficiency.

There is no surprise that more and more modern merchants are turning to Inventory Management Software to help with their inventory planning requirements. Inventory management software can help eliminate time-consuming manual tasks and increase inventory accuracy.

It is common for online firms to use inventory automation to automate inventory planning processes that are time-consuming and prone to human mistakes, such as the pick up of incorrect inventory and inventory shrinkage. For the smooth running of operations, a seller needs an inventory management system.

This requires a substantial one-time investment for developing an IMS and technical staff must be employed to manage it. This becomes a hurdle for small and medium-scale sellers. They are already short on capital and have narrow profit margins to compete with established eCommerce giants. Third-Party inventory planning software can help them with their requirements.

Instead of investing in their inventory management software, working with a third-party logistics (3PL) supplier like WareIQ can save time, effort, and money.

Lack of Trained Resources

The warehousing process will likely slow down or fail if the employees are not appropriately trained. Sellers must equip personnel with knowledge of the newest procedures, data analytics, distribution metrics and technology involved in supply chain management to bring value to inventory planning.

However, investing in training and technology implementation can be costly and time-consuming. Though many online firms have team members who oversee logistics, it is commonplace for online brands at all phases of development to collaborate with a 3PL that can provide the technology, data, and knowledge needed to plan and manage inventory efficiently.

Suggested Article: What is Inventory Aging?

5 Best Inventory Planning Methods to Consider in 2023

Now that we’ve discussed the challenges, benefits, and fundamentals of inventory planning, let’s talk about how to actually implement it. There are a handful of inventory planning methods. Consider the right one depends upon your products, business type, and processes involved.

The Work in Progress Model (WIP)

Merchants who deal in partially finished items, finished goods, or goods-in-transit should use this model. This inventory model emphasizes inventory holding, and there are three reasons for this:

- Purchasing raw materials in bulk saves money and lowers per-unit costs.

- It helps avoid stockouts and provides precautions against demand uncertainty.

- It encourages holding inventory to reduce the chances of price hikes for materials and labor.

The Self-Consistent Inventory Model

Economic Order Quantity (EOQ)

The economic order quantity (EOQ) method determines the best inventory quantity to order. It considers product demand, unit pricing, and holding costs to assist sellers in figuring out how much to order.

The goal of EOQ is to assist sellers in determining the number of products that will allow them to meet demand without overordering and inflating their holding costs. To make this strategy work, a seller should have a firm grasp on the following:

- Order costs – Expense per merchandise order

- Demand rate – Units sold during a particular time period

- Holding costs – expenses involved in holding the product

The EOQ formula is :

EOQ = Square Root of [{ 2 (Order Costs) X (Remand Rate)} / Holding Costs ]

Minimum Order Quantity (MOQ)

The minimum order quantity (MOQ) estimates how much inventory a seller should order at any given time. This is perfect for sellers that wish to be careful with their ordering habits or who want to maximize their cash on hand while avoiding excessive inventory spending.

There is not a set formula for MOQ, but a seller can calculate the correct MOQ for their eCommerce business by:

Calculating Demand: It considers the seller’s historical sales data and current patterns to determine how much inventory they will need.

Being Aware of Holding Costs: Calculate the costs of storing a product. Keeping small and minuscule objects in a warehouse will be less expensive than keeping them in a climate-controlled setting.

Knowing the Breakeven Point: Calculate how many products are needed to sell to reach the breakeven point before buying the product.

Determining MOQ: The criteria listed above will assist sellers in determining the proper minimum order quantity for their products.

FIFO or LILO

First-in, First-out (FIFO), and Last-in, Last-out (LILO) are supply management methods in which products purchased first are sold first or vice versa. An ideal formula for retailers who sell perishable products, FIFO requires keeping track of the purchase date of each product and dispatching inventory according to it.

The main motto is to monitor the expiration dates of perishable products. Structure the stock in the warehouse in such a way that makes it easy to implement FIFO or LILO.

Setting Reorder Points

Reorder points are crucial tools in inventory planning since they assist the store in avoiding stockouts. Product demand, sales velocity, order lead time, and safety stock levels determine the optimal reorder point.

Calculating the reordering point requires two components:

- Safety Stock: (max daily orders x max lead time to get it) – (average daily orders x average lead time to get it)

- Lead Time Demand: the average number of units sold daily x the lead time of a product

To determine the reorder point, add lead-time demand to safety stock. Use the following formula:

Reorder Point = Safety Stock + Lead Time Demand

Just-in-Time (JIT) Model

Just-in-time ordering is an approach in which items are ordered just when required. Because it allows a seller to avoid sitting on too much stock at any given moment, this strategy can help them save a lot of money on holding expenses.

It requires trustworthy supply chain management.

Sellers will need a quick ordering process and dependable vendors who can deliver products on schedule for JIT to succeed. Here, the idea is to decrease waste and increase efficiency by ordering products as per demand and never prematurely.

Conclusion: Inventory Planning with InventoryLogIQ

A retail business that makes smart inventory decisions in advance will almost certainly succeed. The main problem is monitoring bulk orders while carefully monitoring data and upcoming inventory trends.

Without adequate inventory planning, substantial consequences might arise, ranging from increased transportation costs to catastrophic stockouts and shipping order delays.

InventoryLogIQ can help you save money on inventory planning. It provides the tools, experience and support you need to make smarter business decisions and grow your organization faster, from inventory planning to real-time inventory management.

Be a part of our sophisticated Warehousing Management System by partnering with InventoryLogIQ while maintaining control and visibility over your multi-location inventory across the nation and supply chain. With our inventory planning platform, brands experience 80%+ regional utilization & 40% lower holding costs.

Inventory LogIQ achieves this by utilizing the following:

- AI-based Algorithms for Product Bundling Recommendations: This generates rich insights in the form of minimalistic reports, which help businesses identify the product bundling strategy aimed at improving the sales of non-moving products and free-up working capital locked in slow-moving inventory. Ultimately, this helps in inventory liquidation and reduction in storage space required.

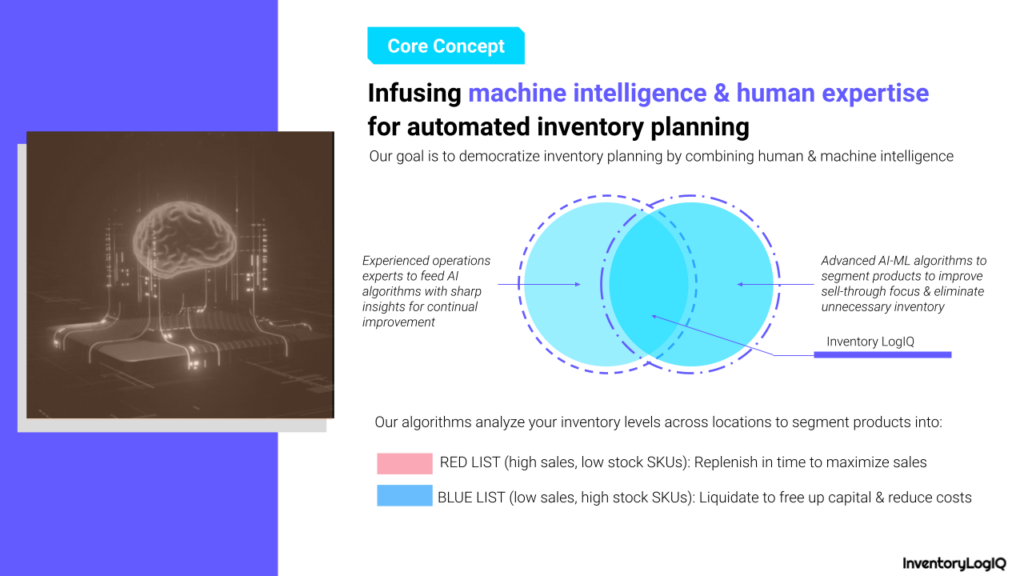

- Product Segmentation Tool & Planning Engine: This allows you to segregate your SKUs as per their performance and helps you enhance your product-level sell-through focus. Furthermore, with automated replenishment triggers, you will never miss out on any sale by stocking the right SKU at the right time.

- Sophisticated Fulfillment Network Planner: Our network planning engine analyses the regional buying patterns and enables you to optimize your fulfillment network so that you can place inventory closest to your customers and unlock speedy deliveries for a significantly larger share of regional demand.

Suggested Read: What is Merchandise Assortment Planning?