Inventory Cycle Count: A Detailed Guide Including Definition, Methods, Advantages and Processes in 2023

If you are an eCommerce seller, inventory becomes your biggest asset to invest in. Having inventory cycle counts is important because it can prevent losing out on sales and revenue. Inventory disparities are a problem that can be resolved relatively quickly. Every firm should strive to run accurate inventory cycle counts. For warehouse and returns management, general logistics and sales forecasting to be successful, accurate inventory counts are essential.

Accurate cycle counting has an impact on almost every part of your company and its effects can last for years. It is a crucial component of inventory management procedures used by many firms since it ultimately ensures that consumers can obtain what they want when they want it while minimizing the costs associated with maintaining goods on hand. Today, we will learn about the method of controlling inventory through inventory cycle counts, what inventory cycle counting is, how it can improve your inventory accuracy to avoid stockouts and the best practices for implementing it.

What is an Inventory Cycle Count?

An inventory cycle count, also called cycle counting, is an inventory counting method that decreases the need for conventional audits by rotating product counts in a cyclical schedule. For large warehouses with a huge number of several distinct product types, inventory cycle counting is the preferred method. Cycle counting helps businesses operate effective, cost-friendly and time-saving inventory counts. Inventory cycle counts are commonly referred for inventory cycle audits.

Different Methods of Inventory Cycle Counting

ABC Cycle Counting

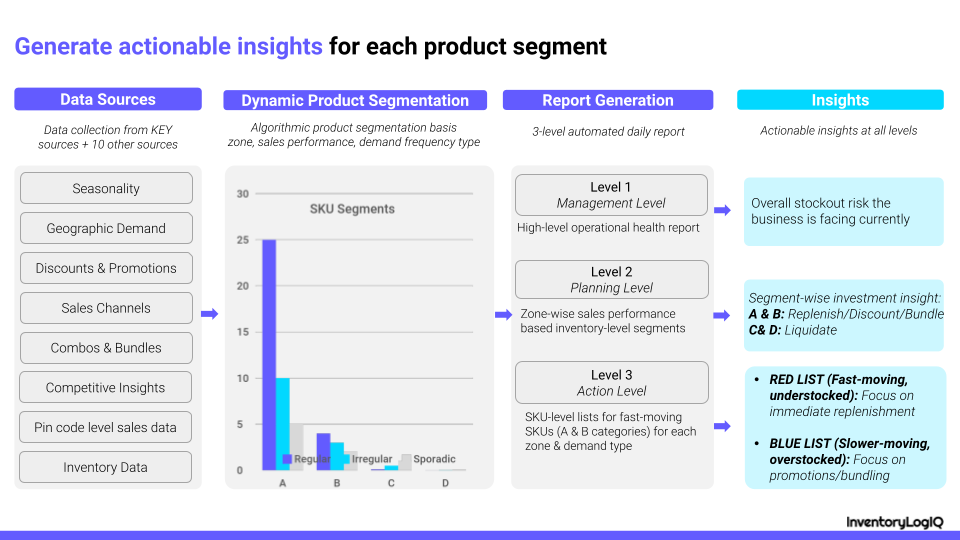

This approach is used for inventory counts that are based on the Pareto Principle when counting more expensive, faster-moving items. According to ABC cycle counting, 20% of the parts in a warehouse correspond to 80% of the sales. These are the “A” items (the “B” items make up 30% of the inventory and 15% of the sales and so on.). Your most valuable assets or fastest-moving SKUs might be “A” goods.

Software for inventory control can classify the counts as A, B or C goods. Consider counting your “A” items more frequently while counting your “B” and “C” goods less frequently. You can use additional indicators like transactions and production figures to start ABC cycle counting. You can determine which products significantly affect your company’s overall inventory cost using a variety of measures. Read to learn about what is ABC Analysis.

Usage-Based Cycle Counting

Any time an item is transferred (part of inventory transfer), whether it is through a manufacturer, distributor or eventually to the client, there is a chance that the inventory will vary. The most frequently accessed products are given priority in usage-based cycle counting to curtail that. Access could refer to being physically handled in any form, including being processed into or out of a warehouse.

Hybrid Cycle Counting

The usage-based and ABC counting techniques are combined in the hybrid cycle counting method to give the most frequently accessed, high-value items priority. When the ABC categories get too big, this approach is required. Managers can prioritize the A-category products with the most traffic by further segmenting their ABC categories. These items’ inventory volatility hurts the company’s bottom line the most. As a result, it makes sense that leaders would want to concentrate on precise counts within this area.

Control Group Cycle Counting

Control group cycle counting is based on the idea of establishing a control group and then using the information to expand to bigger sets. Companies will count the same products repeatedly over a short period of time using this practice. This is done in order to identify counting problems, correct them and improve the counting procedure before applying it to a larger group of items. For companies that are new to inventory cycle counts, this strategy may be advantageous. It enables you to practice your cycle counting skills over time until they are suitable for usage on a broader scale.

Random Sample Cycle Counting

Random sample cycle counting works well for businesses that sell lots of similar goods. This method enables you to choose a random sample of objects for each cycle count. The advantage in this situation is that random sample cycle counting may be done during regular business hours and poses little inconvenience to your warehouse.

As the item selection procedure is random in this configuration, certain items may be tallied frequently and others infrequently. A diminished population, a subset of random sample cycle counting, is a different approach. Here, items are counted and then excluded from further inventory cycle counts until everything in the inventory has been counted.

Geographic Cycle Counting

The geographic counting approach emphasizes counting goods in a specific physical location. This approach, combined with random counts spaced at random intervals, can assist in pinpointing issue areas like theft or damage.

Advantages of an Inventory Cycle Count

Enhances Productivity

An inventory cycle count keeps track of your inventory by maintaining inventory accuracy and efficiency in a variety of areas which leads to better productivity and output. The following aspects of your business will benefit the most from conducting an inventory cycle count:

Assists in Purchasing

Performing consistent inventory cycle counts enables you to purchase only what you need to prevent jamming money on overstocked or unsold goods. This will help reduce costs and wastage associated with over-ordering.

Helps With Production

Doing routine inventory cycle counts will help you plan your production to meet your demand and produce the proper quantities at the appropriate time to prevent making products that will occupy storage space.

Assists in Sales & Marketing

Inventory cycle counts can enable you to discuss with your sales team what is and is not selling. It will improve internal business relationships and generate more revenue as a result. Check on extra products and plan promotions to assist in generating sales.

Helps in Financing

An inventory cycle count is necessary for many accounting computations. Cycle counting makes it possible for you to run reports and calculate data with the assurance that there won’t need to be any large recalculations throughout tax season.

Saves Time and Effort

Cycle counting is more efficient than lengthy annual inventory counts because it can break up the monotony of protracted inventory audits. Therefore, you generally won’t need to close your business or ask your staff to skip work in order to count your inventory. Additionally, regular inventory cycle counts make it simpler to locate misplaced, harmed or stolen goods in a sizable warehouse inventory.

Saves Monetary Resources

An inventory cycle count will also help you save money. To fully count every item in your inventory, annual counts frequently necessitate overtime hours. Setting aside time in daily or weekly chunks to count groupings of goods works out to be more economical.

Processes Involved in an Inventory Cycle Count in 2023

Warehouses start inventory cycle counting to avoid the root causes of errors in tabulating inventory. After you complete a full physical inventory check to know and correct any discrepancies, you must use a regular counting program for maintenance. Steps during an inventory cycle count are listed below:

Review All Your Documents

Starting with an accurate database is important. Review and correct all data entries for inventory transactions to start the inventory cycle count process.

Upload the Inventory Cycle Count Report

Make a report on the inventory cycle count. Upload the report to your database or software solution if you plan on conducting the count.

Start the Inventory Cycle Count

The report’s inventory locations, summaries and numbers should be reviewed by a counting person, who should then contrast them with what is physically present on the shelves.

Investigate and Correct Any Discrepancies

Determine any differences discovered during the count and work with the stock manager to resolve them. Search for mistake patterns.

Change Processes and Add Policies

Whenever necessary, put any inventory counting policies or processes into action. For this, you may need to change some processes in your standard workflow.

Update Records

Update the inventory record database to reflect the items that are currently on the shelves.

Calculate the Accuracy Percentage

For this, first match your data with a standard inventory cycle count and other competitors. After getting the inventory cycle count, keep auditing the inventory regularly and get the accuracy percentage each time. Then compare them and identify the best practices.

Conclusion: Automate Your Inventory Cycle Counts With InventoryLogIQ

Inventory cycle counts are a valuable tool for businesses of all sizes and industries. By regularly counting a portion of their inventory, businesses can maintain accurate inventory records, identify discrepancies, improve operational efficiency and provide better customer service. As such, businesses should consider implementing inventory cycle counts as part of their inventory management strategy to streamline their operations and improve their bottom line.

InventoryLogIQ can automate your inventory counting process by utilizing an advanced AI-based OMS to enable automated inventory counts and real-time inventory updates across multiple fulfillment centers and eCommerce platforms. The benefits of outsourcing inventory management to 3PL providers experts like us are better accuracy and more efficiency.

This greatly accelerates the process of inventory management while reducing any chance of errors occurring. You can benefit from a shorter order cycle time as a result, which might increase the number of days your inventory can be sold for. It also frees up your time so you can concentrate on the other operations of your eCommerce store.